Long Time Working Automotive Alternator Bearing Parts Kaydon Roller Full Ball Bearing Passive Magnetic Ball Bearing 6300

In an era where efficiency and longevity are paramount in industrial machinery, magnetic bearings emerge as a game-changing technology. These advanced systems leverage the power of magnetic levitation to virtually eliminate friction and wear, propelling performance to new heights. As we delve into the mechanics and benefits of magnetic bearings, we uncover how they are revolutionizing industries by supporting high-speed operations and reducing maintenance demands. Join us as we explore the transformative impact of magnetic bearings on modern machinery, and how sourcing from Alibaba can offer a competitive edge in industrial applications.

Magnetic bearings are a sophisticated type of bearing that utilizes magnetic levitation to support loads without direct contact. This technology allows for the levitation of a rotating shaft, enabling motion with minimal friction and no mechanical wear, which is particularly beneficial for applications requiring high-speed rotation without a maximum speed limit. Active magnetic bearings are the most common, relying on electromagnets that necessitate continuous power and a control system to maintain stability. They offer low friction and the ability to automatically correct mass distribution irregularities, leading to minimal vibration. Passive variants, while not requiring power, are challenging to design due to physical limitations such as Earnshaw's theorem. Combined designs use permanent magnets to support static loads, with active bearings stepping in for dynamic stability. Despite their complexity, magnetic bearings are integral in industries like power generation, petroleum refinement, and gas handling, due to their ability to operate cleanly without lubrication, which is essential in environments where contamination is a concern.

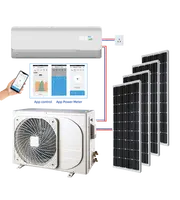

Alibaba showcases a diverse range of magnetic bearings designed to cater to various industrial needs. These bearings include flexible rubber magnet strips in both A4 and A3 sizes, suitable for a multitude of applications. For more demanding tasks, the platform offers strong disc magnets with countersunk holes made from high magnetic strength materials. Additionally, there are full stock button magnets for clothing applications, ensuring quick delivery for urgent needs.

The selection extends to super strong magnets, which are ideal for high-performance requirements due to their powerful magnetic capabilities. For specialized applications, there are magneto bearings in various dimensions, and options tailored for machinery repair shops. Automotive industries can find long-lasting alternator bearing parts, while passive magnetic ball bearings cater to more passive applications.

For those in the textile industry, magnetic button solutions are available, alongside stainless steel ball bearings ranging from 6300 to 6315, which are corrosion-resistant and suitable for food and beverage applications. Hybrid ceramic magnetic bearings, offer a blend of durability and performance. The inventory also includes insulated deep groove ball bearings and a variety of magneto ball bearings for motor applications, ensuring that there's a magnetic bearing solution for virtually any industrial requirement.

Active magnetic bearings are designed to support high-speed rotating machinery such as permanent magnet motors, compressors, and turbines without physical contact. They employ non-contact position sensors that monitor the shaft's position, relaying this data to a control system. This system, in turn, adjusts the magnetic actuator's current to maintain the rotor's precise position. By doing so, magnetic bearings significantly reduce friction and wear compared to conventional bearings, which require direct contact with the shaft and lubrication. The absence of contact in magnetic bearings means there's no wear, contributing to a longer lifespan and reduced maintenance for high-speed machinery. This technology is particularly beneficial in industrial applications where minimizing downtime and maintenance is crucial for performance and cost-efficiency.

Magnetic bearings are designed to support a rotating shaft without physical contact, significantly reducing system friction. While often described as 'low friction' rather than 'no friction,' magnetic bearings do experience some frictional forces. The friction in magnetic bearings arises not from contact, but from other factors within the system. For instance, conducting materials within the rotating component can generate power losses due to eddy currents. These currents are the result of the rotating part moving through the magnetic field created by the bearing.

Additionally, any asymmetry in the magnetic field can create an alternating magnetic field, which contributes to friction. The rotating part, if magnetized, can also induce power dissipation in any external conductive materials. Despite the challenges in completely eliminating friction, magnetic bearings are engineered to minimize these losses, accepting them as part of the trade-off for the considerable benefits they provide. Losses typically come in two forms: windage, or aerodynamic losses, and electromagnetic losses, which include hysteresis and eddy currents. Understanding these mechanisms is crucial for optimizing the performance of magnetic bearings in various applications.

Magnetic bearings offer a revolutionary approach to minimizing wear in machinery. By utilizing magnetic levitation, these bearings support moving parts without any physical contact, eliminating mechanical wear. This attribute is particularly beneficial in high-speed applications where traditional bearings would suffer from rapid wear and tear. The absence of contact means that friction is significantly reduced, which not only extends the lifespan of the machinery but also enhances its reliability and efficiency. Magnetic bearings are adept at handling irregularities in mass distribution, which contributes to a smoother operation with minimal vibration. The design of active magnetic bearings, which are the most common type, incorporates electromagnets to maintain the position of the load. This active control allows for precise adjustments to be made in real-time, ensuring consistent performance and further reducing the potential for wear. In the event of power or control system failures, magnetic bearings are typically paired with a backup bearing to maintain functionality. The integration of magnetic bearings into industrial machinery marks a step forward in reducing maintenance needs and improving the longevity of equipment.

Active magnetic bearings (AMBs) are pivotal in various high-speed industrial applications, significantly enhancing operational efficiency. In turbocompressors, used for gas injection and compression across industries like chemical processing and HVAC, AMBs eliminate the need for lubrication, thereby reducing contamination risks and maintenance related to oil use. This feature is particularly beneficial in sensitive environments such as food processing and pharmaceuticals.

Turbo blowers also benefit from the frictionless operation provided by magnetic bearings, which is crucial in applications involving aeration, drying, and pneumatic conveying. These systems are prevalent in sectors such as wastewater treatment and agriculture, where they contribute to reducing wear and maintenance costs, which are substantial parts of operating expenses.

In Organic Rankine Cycle (ORC) power plants, which convert waste heat into electricity, AMBs facilitate higher impeller rotational speeds without the need for lubricants, enhancing energy efficiency and reducing mechanical losses. The bearings' ability to operate without friction is also advantageous in preventing contamination of refrigerants and maintaining the thermal stability of organic fluids in these systems.

Beyond these applications, magnetic bearings offer broad utility across various industries, providing a frictionless, maintenance-free operation that supports high rotational speeds and improves process efficiency. Their robustness in harsh environments and ability to reduce equipment downtime make them a valuable component in modern industrial machinery.

Magnetic bearings are sophisticated devices that employ magnetic levitation to support loads without physical contact, eliminating friction and wear. The core features of these bearings include active and passive types, with active bearings utilizing electromagnets that require power and control systems to maintain stability. Passive bearings, on the other hand, rely on permanent magnets and are more challenging to design due to Earnshaw's theorem constraints. Materials used in magnetic bearings are often advanced, including diamagnetic materials and rare-earth magnets, which are critical for their function. The design intricacies of magnetic bearings involve a delicate balance of forces, where electromagnets generate a magnetic field that interacts with conductors to create levitation. This system is finely controlled by gap sensors and microprocessor-based controllers, ensuring precise operation. The materials and design of magnetic bearings contribute to their unique advantages, such as the ability to operate at high speeds, support heavy loads, and maintain performance in a vacuum or clean environments where traditional lubricated bearings would fail.

Passive magnetic bearings offer a unique set of advantages for industrial applications, which are well-represented in Alibaba.com's diverse catalog. These bearings are designed to handle heavy-duty operations without the friction that typically accompanies traditional bearings. This characteristic is crucial for machinery parts that operate at high speeds or under significant loads, ensuring a smoother performance and less wear over time.

The variety of passive magnetic bearings available on Alibaba.com includes options for different applications, ranging from automotive alternators to high-speed industrial machinery. The selection includes curved magnets known for their high-temperature resistance, and magnets which are recognized for their strong magnetic fields. Ferrite magnets offer a cost-effective solution, while specialized options like hybrid ceramic magnetic bearings cater to specific performance requirements.

By sourcing magnetic bearings through Alibaba.com, businesses can benefit from the ability to choose from a wide range of materials and features to match their specific needs. The platform's offerings demonstrate a commitment to versatility and performance, with bearings that minimize momentum loss on the surface of the vehicle and provide a solid layer of support for rotating parts. This translates to enhanced longevity and reliability of machinery, which is a significant advantage for any industrial operation.

Magnetic bearings represent a significant technological leap in reducing friction and wear in industrial machinery. By harnessing magnetic levitation, these bearings enable high-speed operations while minimizing maintenance, thereby enhancing overall efficiency and equipment longevity. The diverse range of magnetic bearings available on Alibaba.com caters to various industrial needs, offering tailored solutions that range from high-temperature resistant magnets to strong magnetic fields. The adoption of these bearings across multiple industries underscores their versatility and the value they add in terms of performance and reliability. As industries continue to seek out innovations that drive productivity and reduce operational costs, magnetic bearings stand out as a pivotal solution, marking a new era of advanced industrial machinery maintenance and design.