Understanding Braided Sleeving

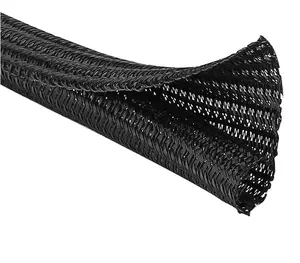

Braided sleeving, a versatile solution for cable management and protection, offers a blend of durability and flexibility. This product category encompasses a range of sizes, materials, and designs, each tailored for specific applications. Whether for industrial environments or home electronics, braided sleeving serves to organize, protect, and enhance the longevity of wire assemblies.

Materials and Design

The choice of material for braided sleeving is crucial, as it dictates the sleeve's properties. Options range from heat-resistant fiberglass to flexible polyethylene terephthalate (PET). Each material brings distinct advantages, such as abrasion resistance or thermal protection, making the selection process critical to match the sleeving to the environment it will be used in.

Selection Criteria

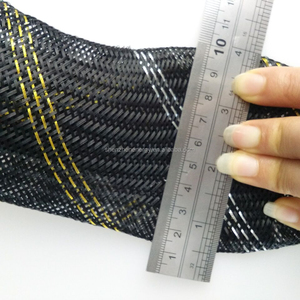

Selecting the appropriate cable protection sleeve involves considering several factors. The number of cables to be enclosed will determine the required diameter of the sleeving. Additionally, the type of connectors used should influence the sleeving choice to ensure compatibility and ease of installation. For areas with considerable movement or traffic, a more robust cable organizer sleeve may be necessary to prevent wear and tear.

Applications and Uses

Wire protection tubing has diverse applications, from automotive wiring harnesses to home theater systems. Its primary function is to consolidate multiple cables into a single, neat bundle, reducing clutter and enhancing safety. In industrial settings, heavy-duty cable sleeves are employed to safeguard cables from harsh conditions, including high temperatures and mechanical damage.

Advantages of Braided Sleeving

The advantages of using braided sleeving are manifold. It not only improves the aesthetics of cable runs but also simplifies maintenance and inspection by allowing individual cables to be added or removed without much hassle. The interwoven design provides a balance of protection and flexibility, unlike rigid conduit options.

Choosing the Right Sleeve on Alibaba.com

Alibaba.com serves as a marketplace to connect with a variety of suppliers offering a wide selection of braided sleeving. Without endorsing any specific brand or making absolute claims, the platform facilitates finding a suitable cable sleeve that aligns with the user's requirements. Prospective buyers can utilize the search feature to explore the extensive range and make informed decisions based on the detailed product information provided.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4