Custom Big Mold Sheet Metal Steel Press Punching Pot Forming Die Stamping Metal Welding Dies Mold Progressive Cutting Mold

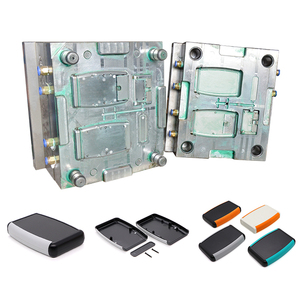

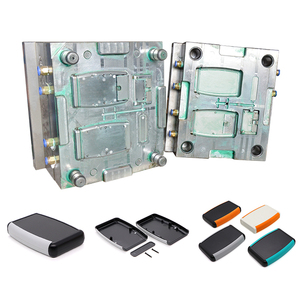

Manufacturer Supplier Mouldings Designer Service Mould Making Custom Products PVC PC ABS Parts Plastic Injection Molding

Concrete block moulds are essential tools in the construction and manufacturing industries, enabling the production of blocks used in building a variety of structures. These moulds come in different shapes and sizes, tailored to create blocks for specific applications and design requirements. Understanding the nuances of these moulds is crucial for businesses looking to procure them for large-scale projects or manufacturing processes.

There is a diverse range of concrete block moulds available, each suited to different project needs. From lightweight blocks for residential construction to heavier, more durable blocks for commercial buildings, the variety is extensive. The applications of these moulds are just as varied, including but not limited to, retaining walls, landscaping, and architectural elements. The adaptability of these moulds allows for their use in creating both standard building blocks and more specialized units such as interlocking pavers.

The features of concrete block moulds are designed to enhance efficiency and quality. Moulds with precise dimensional tolerance ensure uniformity in block production, which is critical for the structural integrity of the built environment. Materials used in mould construction include robust metals and alloys, with iron being a common choice due to its durability and longevity. Some moulds are also designed to be stackable, saving space in storage and transportation.

Utilizing well-crafted concrete block moulds brings several advantages. They ensure consistent quality in block production, which is vital for meeting industry standards and regulations. Additionally, durable moulds reduce the need for frequent replacements, thereby lowering long-term costs. The precision of these moulds also minimizes waste during production, contributing to more sustainable manufacturing practices.

Customization is a significant aspect of concrete block moulds, allowing for the creation of unique designs and shapes. Suppliers on Alibaba.com can tailor moulds to specific design requirements, ensuring that the final product meets the exact needs of the buyer. Standardization options are also available, enabling businesses to streamline their operations by using moulds with uniform lift bars, connection sizes, and clamp slots for different products.

Selecting the appropriate concrete block moulds is a critical decision. Factors to consider include the type of block required, the material of the mould, and the production capacity. Suppliers on Alibaba.com provide detailed information to assist buyers in making informed decisions, ensuring that the chosen moulds align with their operational needs and production goals.