Flywheel Grinding Machine Defined

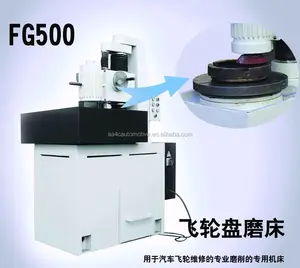

Flywheel Grinding Machines are a specialized type of machinery crafted to ensure precise and effective grinding and polishing of flat surfaces. Commonly utilized in the metalworking sector, they excel in shaping and refining metal by eliminating material and smoothing the surface. The fundamental concept behind a flywheel grinding machine revolves around a rotating disk, referred to as the grinding wheel, which is affixed to a headstock that moves reciprocally across the workpiece. Typically, this motion is powered by an electric motor.

Distinct from standard grinding machines, flywheel grinders stand out due to their unique movement pattern and approach to shaping metal. While traditional grinding wheels move in a circular motion, flywheel grinders adopt a horizontal or vertical reciprocating motion, offering a superior finish and enhanced accuracy. These machines are indispensable for tasks demanding high precision, such as in the automotive industry for grinding and polishing connecting rod caps and bearings.

The essential components of a flywheel grinding machine encompass the grinding head, housing the grinding wheel, and the motor propelling the head and wheel. The head is situated on a column that permits multidirectional movement to accommodate specific task requirements. The motor is linked to the head, furnishing the necessary power for its rotation. Various types of grinding wheels are available to cater to diverse materials and surface characteristics, ensuring versatility across a wide range of metal alloys.

Varieties of Flywheel Grinding Machines

Flywheel grinding machines fall into two categories: those designed for automatic rotation and those necessitating manual rotation. These categories address distinct market needs:

-

Automatic Rotation Machines: Featuring a rotating table and a stationary grinding stone, these machines secure the flywheel to the table, spinning it at a constant speed. Operators maneuver a standard grinding tool across the surface using a hand wheel. Commonly found in manufacturing plants or auto repair shops conducting high-volume flywheel maintenance.

-

Manual Rotation Machines: In this type, operators manually rotate the standard grinding tool against the flywheel surface. Often observed in workshops handling lower volumes of flywheel resurfacing or prioritizing precision. Manual machines are versatile and adept at various grinding tasks.

-

Portable Flywheel Grinders: Compact, lightweight, and easily transportable, these machines suit on-the-go mechanics requiring mobility without compromising work quality.

Selecting the Right Flywheel Grinding Machine

The proper selection of a flywheel grinding machine is pivotal for meeting your business requirements. Factors to contemplate when choosing a machine include the material type you will be working with (cast iron, steel, or non-ferrous metals), desired finish quality, and production capacity. For instance:

-

Material Compatibility: Ensure the machine can effectively grind the materials pertinent to your industry, whether tailored for hard metals in an industrial setting or softer materials in a smaller workshop.

-

Finish Quality: The requisite level of finish will dictate your choice. Machines offering high precision and adjustable finishes are indispensable for industries like automotive manufacturing or repair shops.

-

Production Capacity: Evaluate the workload volume needing processing. Machines with heightened productivity rates enable the completion of more tasks in less time.

-

Ease of Operation: User-friendly interfaces with clear instructions significantly impact workflow efficiency. Consider the ease of setup and operation of the machine.

By meticulously assessing these aspects against your specific needs and budgetary constraints, you can make an informed decision on the most suitable flywheel grinding machine for your business.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4