Understanding PLC Analog Modules

Programmable Logic Controllers (PLCs) are the cornerstone of industrial automation, and PLC analog modules play a pivotal role in this domain. Unlike their digital counterparts, analog input and output in PLC systems allow for the monitoring and control of variables such as temperature, pressure, and flow rate, which vary across a range. This introduction delves into the intricacies of PLC analog modules, their types, applications, and features.

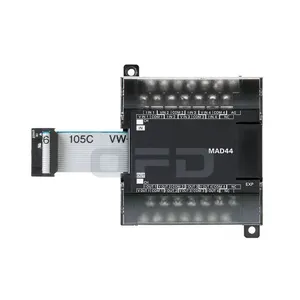

Types of PLC Analog Modules

The versatility of PLC systems is enhanced by various modules, including the analog input module in PLC and analog output module PLC. For instance, the Allen Bradley 1769 IF8 module is designed for precise input operations, while the Allen Bradley 1769 IF4 focuses on compact input integration. On the output spectrum, modules like the s7 1200 analog output cater to a range of control tasks. The fx5 4da and fx2n 2ad are examples of modules that offer both input and output functionalities, suitable for diverse industrial scenarios.

Applications of PLC Analog Modules

PLC analog input output modules are integral to a multitude of applications. They are commonly found in sectors where monitoring and adjusting analog signals are crucial. For example, in process industries, the 4 20ma PLC signal standard is widely used for consistent data transmission. The fx3u analog input module can be employed in such settings to facilitate reliable data acquisition. Similarly, the dvp04ad s2 module is often utilized in machinery that requires precise control over analog variables.

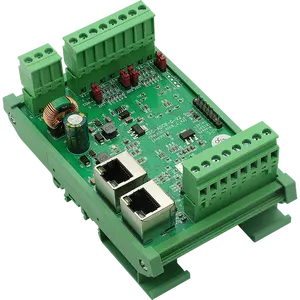

Features and Materials of PLC Analog Modules

PLC analog modules are designed with a focus on durability and functionality. Materials used in the construction of modules like the cp1w ad041 ensure resilience in harsh industrial environments. Features such as signal conversion, where an analog signal PLC is translated into a digital format, are critical for accurate data processing. Modules are also equipped with various channel counts, resolution types, and signal ranges to accommodate specific application needs.

Advantages of Using PLC Analog Modules

Incorporating PLC analog modules into industrial systems offers several advantages. They provide enhanced precision in control tasks, allowing for fine-tuning of processes. The integration of modules like the s7 1200 analog input can lead to improved operational efficiency and data accuracy. Moreover, the adaptability of these modules to various signal types makes them invaluable in a diverse array of industrial applications.

Selecting the Right PLC Analog Module

Choosing the appropriate PLC analog module requires a thorough understanding of the application's demands. Factors such as input/output requirements, signal range, and resolution should guide the selection process. While the platform does not endorse any particular brand or model, it is essential to consider the specifications of modules like the allen bradley 1762 if4 or the analog output in PLC systems to ensure compatibility and performance within the intended industrial setup.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4