Introduction to Portable Melting Furnaces

Portable melting furnaces are essential tools in the field of metalworking, offering the flexibility to melt various metals at high temperatures. These compact units are designed for ease of use and transport, making them ideal for on-site jobs and small-scale operations. With advanced features such as electrical induction heating and hydraulic tilting mechanisms, these furnaces cater to a range of melting needs.

Types and Applications

The versatility of portable melting furnaces is evident in their various types and applications. From open to enclosed furnace designs, these machines serve different purposes, including melting, refining, and casting metals. Some models come equipped with dual pots, facilitating both the melting process and the transfer of molten metal. These furnaces are widely used in industries such as jewelry making, metal recycling, and small foundries.

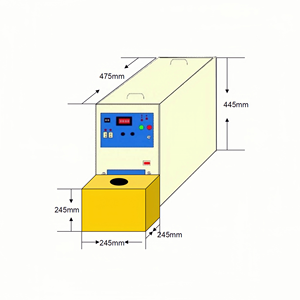

Technical Features and Materials

Induction melting furnaces are engineered to reach temperatures typically ranging from 1,750 to 2,100 degrees Celsius, suitable for melting metals like iron, steel, aluminum, and precious metals. The construction of these furnaces often involves robust materials capable of withstanding extreme heat, while the tilting mechanism allows for a 95-degree movement for efficient pouring. Additionally, a water-cooling system is integrated to manage the temperature of the molten metal.

Operational Advantages

The operational efficiency of a small melting furnace is enhanced by its rapid melting speed, which can vary from 40 to 60 minutes depending on the metal and furnace type. The inclusion of a PLC system simplifies the operation, providing a user-friendly interface for monitoring and control. Safety features such as circuit breakers are also in place to protect against electrical faults, ensuring a secure melting process.

Choosing the Right Furnace

Selecting the appropriate metal melting furnace depends on the specific requirements of the task at hand. Options range from lightweight models, ideal for modest operations, to larger units capable of handling significant volumes of metal. When considering a gold melting furnace, for instance, it is crucial to assess the temperature requirements and capacity to ensure optimal performance for precious metal processing.

Conclusion

In conclusion, the array of portable melting furnaces available on the market caters to a diverse set of metalworking activities. While browsing for these machines, it is important to consider the specific metal types, melting speeds, temperature capabilities, and safety features to find a unit that aligns with your operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4