Introduction to 2 Roll Rubber Mills

The 2 roll rubber mill is an essential piece of equipment in the rubber processing industry, designed to simplify the milling process. This type of mill is instrumental in transforming raw rubber into a workable form, playing a pivotal role in both small-scale workshops and larger manufacturing operations. The versatility of the two roll rubber mixing mill allows it to be integrated into various production environments, adapting to the specific needs of each task.

Types and Applications

There are several types of 2 roll rubber mills, each tailored to different milling requirements. These mills are commonly utilized for tasks such as sheeting rubber, mixing additives, and creating uniform compounds. The application of these mills spans across industries, from automotive to consumer goods, where precise rubber thickness and consistency are paramount.

Features and Materials

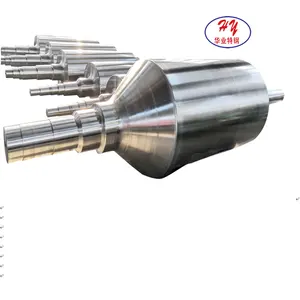

A two roll rubber mixing mill is constructed with attention to durability, employing robust materials that withstand the rigors of milling operations. The design features two horizontally positioned rolls that rotate in opposite directions, ensuring even mixing and sheeting of rubber. The surface of the rolls is typically crafted from chilled cast iron or steel, materials known for their hardness and wear resistance.

Advantages of Modern Mills

Modern 2 roll rubber mills are engineered to enhance efficiency, with features that reduce manual labor and energy consumption. The streamlined operation of these mills results in a significant uptick in productivity. Additionally, the contemporary designs include advanced control panels that facilitate ease of use, ensuring straightforward operation without extensive training.

Environmental and Economic Benefits

The latest models of two roll rubber mixing mills are developed with an eye on sustainability, featuring reduced energy consumption. This not only aids in lowering operational costs but also aligns with environmental conservation efforts. The energy-efficient nature of these mills translates into cost savings for businesses, contributing to a more sustainable production model.

Choosing the Right Mill

Selecting the appropriate 2 roll rubber mill involves considering production volume, desired material properties, and specific industry requirements. With a diverse array of designs and sizes available, finding a mill that aligns with a company's unique needs is less challenging. Prospective buyers are encouraged to explore the variety of options to identify the mill that best fits their production demands.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4