Air Filter Mesh Machine: An Overview

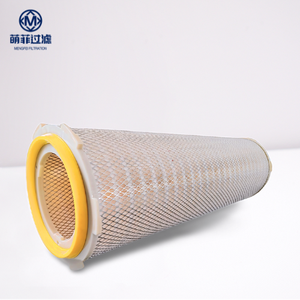

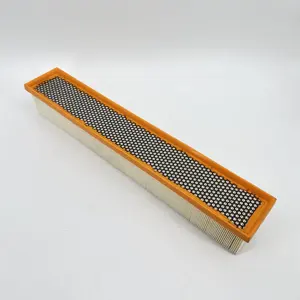

The air filter mesh machine is a specialized device designed to produce mesh materials used in air filtration systems. This machinery is a critical component in the production line of air filter manufacturing, catering to a broad spectrum of industries that require clean air environments, such as automotive, healthcare, and HVAC systems. The air filter mesh serves as a barrier against pollutants, ensuring that only clean air passes through.

Types and Applications

There are various types of air filter mesh machines available, each serving a specific function in the production of filter mesh. These machines are capable of handling different materials and mesh sizes to produce filters suitable for various applications ranging from industrial to residential air purification systems. The adaptability of these machines allows for their use in diverse settings, including construction sites, manufacturing plants, and building material shops.

Technical Features

The technical features of an air filter mesh machine include components such as motors, programmable logic controllers (PLCs), and engines that drive the production process. These machines are engineered to deliver precision and efficiency, ensuring that the mesh produced meets industry standards and specifications. The design of the machine focuses on user-friendly interfaces and robust construction for long-term industrial use.

Material and Design Considerations

When it comes to the materials used in air filter mesh machines, durability and compatibility with various wire materials are paramount. The machines are constructed to handle a range of materials, from synthetic fibers to metal wires, depending on the desired characteristics of the final air filter mesh product. The design of these machines takes into account factors such as ease of maintenance, energy efficiency, and operational safety.

Advantages of Modern Mesh Machines

Modern air filter mesh machines offer several advantages, including automation capabilities that reduce manual labor and increase production rates. They are also equipped with advanced controls for precision, which is crucial for creating effective air filters. The versatility of these machines allows for the production of a wide variety of mesh types, satisfying the needs of different filtration requirements.

Choosing the Right Machine

Selecting the appropriate air filter mesh machine involves considering factors such as production capacity, the types of materials to be used, and the specific mesh specifications required. Potential buyers should assess the machine's compatibility with their existing production lines and the types of air filters they intend to manufacture. It is important to choose a machine that aligns with the operational goals and production standards of the buyer's business.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4