Introduction to Aluminum Wheels Casting Machines

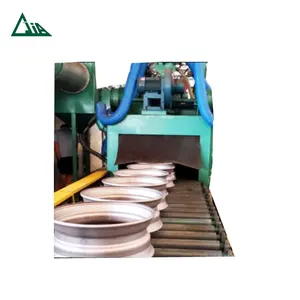

Aluminum wheels casting machines are specialized equipment designed for the production of aluminum wheels through the casting process. These machines facilitate the transformation of molten aluminum into precise wheel shapes using a die, which is a critical component in the automotive and aerospace industries. The process involves various stages, including material collection, die-casting, and cooling, to produce the final product.

Types and Applications

The versatility of aluminum wheels casting machines is evident in the variety of types available, each suited to specific applications. From die casting machines that offer precision for intricate designs to continuous casting machines for efficient, long-run production, the range is extensive. Other types include vacuum casting machines, which are essential for creating wheels with improved mechanical properties, and centrifugal casting machines, known for their ability to produce wheels with fine grain structures.

Features and Specifications

When selecting an aluminum wheels casting machine, it is crucial to consider its features and specifications. These machines come in various sizes and capacities to accommodate different production volumes. The power requirements also vary, ensuring that there is a machine that fits the energy supply constraints of different facilities. Furthermore, the precision of the casting process is a testament to the advanced engineering that goes into the manufacturing of these machines.

Materials and Construction

The construction of aluminum wheels casting machines involves robust materials that can withstand the high temperatures and pressures of the casting process. The durability of these machines is paramount, as they must maintain precision over numerous cycles. The materials used also contribute to the overall stability and longevity of the machine, ensuring that it remains a reliable part of the production line.

Advantages of Modern Casting Machines

Modern aluminum wheels casting machines offer a range of advantages, including increased efficiency and precision in wheel production. The integration of advanced technologies has led to improvements in the speed and quality of casting, reducing waste and enhancing the overall output. Additionally, the availability of parts in different specifications ensures that these machines can be tailored to meet the specific needs of a production facility.

Choosing the Right Machine

Selecting the right aluminum wheels casting machine requires careful consideration of the machine's specifications, the types of wheels to be produced, and the intended production volume. Suppliers on Alibaba.com can assist buyers in making an informed decision, providing detailed information about the machinery without making unsubstantiated claims. It is essential to communicate with suppliers to understand the features and engineering of the machines, ensuring the right fit for the business's requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4