Appliance wheels, commonly known as caster wheels for appliances, serve as a crucial component in the mobility of various home and commercial appliances. These wheels are specifically designed to facilitate the ease of moving heavy equipment, such as refrigerators, washers, and dryers, without the need for significant physical effort. The functionality of appliance wheels is paramount in environments where flexibility and efficiency are essential, such as in kitchens, laundry rooms, and industrial settings.

Types and uses of appliance wheels

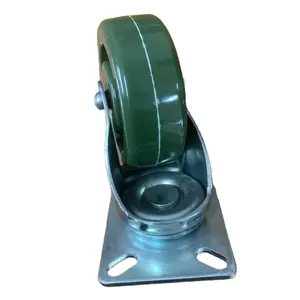

The variety of appliance wheels available caters to a broad spectrum of applications and weight requirements. Heavy duty appliance rollers are engineered to withstand substantial weights, often used with commercial-grade appliances. Conversely, low profile appliance rollers offer a more discreet and compact solution, suitable for appliances that need to fit into tight spaces while still requiring mobility. Additionally, oven rack wheels are tailored to endure high temperatures while providing smooth movement within the harsh conditions of an oven.

Appliance wheels find their applications in a multitude of settings. In residential areas, casters for washing machine and dryers are widely used to facilitate cleaning and maintenance tasks. Such wheels enable homeowners to easily move these heavy units when necessary. In the commercial sector, wheels are critical for the movement of heavy equipment in restaurants, laundromats, and other businesses where appliances must be moved frequently for cleaning, service, or reconfiguration of workspaces.

Features and materials of appliance wheels

Appliance wheels are designed with various features to enhance their functionality and durability. The construction of wheels includes a rotating base that allows for full 360-degree maneuverability, making it easier to navigate corners and tight spaces. Furthermore, some wheels come with locking mechanisms that ensure the appliance stays in place when stationary. The design also typically incorporates shock-absorption features to protect the appliance from the impacts of movement. The materials used in the manufacture of appliance wheels are selected based on their ability to provide strength, durability, and resistance to various environmental factors. Common materials include high-grade plastics, rubber, and metals such as stainless steel. These materials are chosen to resist wear and tear, provide traction on different floor types, and prevent damage to flooring surfaces.

Advantages of appliance wheels

The incorporation of appliance wheels into appliance design offers several advantages. Mobility is significantly enhanced, allowing for greater flexibility in the use and placement of appliances. The ease of movement provided by appliance rollers for washing machine and other appliances also contributes to better ergonomics, reducing the strain on individuals who need to move these heavy items. Additionally, the ability to lock wheels in place increases safety, preventing unwanted movement. The durability of materials ensures that these wheels can provide long-term service, even under frequent use and heavy loads.

By integrating caster wheels for appliances into equipment design, manufacturers can significantly improve the user experience, making the handling and maintenance of heavy appliances less of a burden. Whether it’s for residential or commercial use, appliance wheels play an essential role in the practicality and functionality of modern appliances.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4