What is argon Welder

Argon welders are specialized welding machines designed to facilitate the joining of metals using an inert shielding gas, primarily argon. These machines are utilized by a wide range of professionals, including metal fabricators, construction workers, and maintenance technicians, for both manual and automatic welding processes. The key principle behind their operation is to create a stable arc between the electrode and the metal being welded, which is then shielded from atmospheric contamination by the argon gas.

The effectiveness of an argon welder is influenced by several factors such as the type of metal being welded, the thickness of the metal, and the specific welding process being employed. For instance, TIG (Tungsten Inert Gas) welding is commonly used for high-quality welding of stainless steel and aluminum, while MIG (Metal Inert Gas) welding is preferred for its speed and versatility with various metals.

Argon welders work by generating heat through either a constant current or constant voltage power source. The heat created by the arc melts the metal, allowing the welder to join two pieces together. During this process, the argon gas acts as a shield to protect the molten metal from oxidation and to ensure a clean, strong weld. This results in a high-quality, durable weld suitable for a range of applications across different industries.

Types of Argon Welders

Argon welders come in various types to suit different welding needs and environments. Here is an overview of some common types:

-

Handheld Argon Welders: These are compact and portable, ideal for small jobs or repairs. They typically operate on low amperage and can be used for TIG welding and non-critical applications.

-

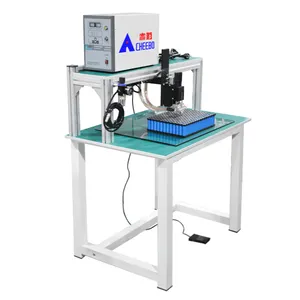

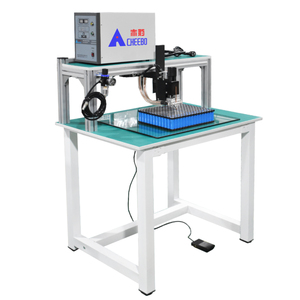

Stationary Argon Welders: Larger and more powerful than their handheld counterparts, these machines are suitable for industrial use where they are set up in a fixed location. They are designed for high-precision work and can handle heavier materials.

-

Portable Argon Welders: These units are larger than handheld models but still offer mobility. They are perfect for onsite jobs such as construction or repair work where equipment needs to be moved frequently.

-

Multifunctional Argon Welders: These machines offer multiple welding processes in one unit, such as TIG, MIG, and stick welding. This versatility makes them suitable for a wide range of applications across different industries.

-

High-Frequency (HF) Start Argon Welders: Equipped with high-frequency start technology, these welders provide a more stable arc and are often used in critical applications where precision is paramount.

How to choose argon Welder

Selecting the right argon welder depends on several factors related to the type of work being performed and the specific needs of your business. Here are some considerations:

-

Material Compatibility: Identify the type of metals you will primarily be working with. For example, if you frequently work with aluminum, an AC/DC TIG welder would be necessary due to aluminum's need for alternating current during welding.

-

Thickness of Materials: Consider the thicknesses of the materials you will be welding. For thinner materials that require precise heat control to prevent warping or burn-through, a pulse TIG welder may be your best choice.

-

Power Requirements: Ensure that you have access to the correct electrical outlets needed for your welder. Some require 220V while others might operate on 110V or even dual voltage.

-

Local Service Location: Depending on where your business is located, you may want to consider a machine that has local service support available. This can be crucial for maintenance and repair issues.

-

After-Sales Service: Look for suppliers who provide comprehensive after-sales services like online support or video technical support which can be very beneficial for troubleshooting and maintenance.

-

Customization: If your business requires specialized equipment, consider suppliers who offer ODM (Original Design Manufacturing) or OEM (Original Equipment Manufacturer) services for custom solutions.

About argon Welder on Alibaba.com

For businesses seeking reliable argon welders, Alibaba.com stands out as a global wholesale marketplace that connects buyers with a vast network of suppliers from around the world. This platform offers an extensive selection of argon welders suitable for various industries and applications, ensuring that whether you're working on construction sites or manufacturing plants, you'll find equipment that meets your specific needs.

Alibaba.com's commitment to facilitating seamless transactions is evident through services like Trade Assurance which protects payments until delivery is confirmed. Moreover, buyers have access to detailed machinery test reports which assist in making informed decisions based on performance metrics like accuracy levels and energy efficiency.

Choosing Alibaba.com as your source for argon welders means tapping into a wealth of resources designed to support businesses in scaling up their operations efficiently. With a focus on B2B sales and bulk purchases, Alibaba.com empowers organizations to negotiate deals that align with their growth trajectory while accessing specialized equipment that can drive their productivity forward.

Common FAQs for argon Welder

What is an argon welder used for?

An argon welder is primarily used for producing high-quality welds on materials that are not suitable for oxygen-rich environments, such as aluminum, stainless steel, and titanium. It is commonly used in industries like aerospace, automotive, and any field that requires precise and clean welding.

How does an argon welder work?

An argon welder works by creating an inert gas environment around the weld area, preventing contamination from the atmosphere. This allows for clean and strong welding without oxidation or weakening of the metal.

What are the benefits of using an argon welder in my business?

Argon welders produce high-quality welds with minimal material contamination. They are ideal for critical applications in industries such as aerospace, automotive, and any field where weld integrity is paramount.

Can argon welders be used on all types of metal?

Argon welders can be used on a variety of metals, but it's important to select a machine with the appropriate power output and welding capabilities for the specific metal or alloy being welded.

How do I choose the right argon welder for my manufacturing process?

Choose an argon welder based on the thickness and type of material you need to weld. Consider the power requirements, additional features like pulse settings or pre-flow control, and whether you need a portable or stationary machine.

What is the difference between AC and DC argon welders?

AC and DC argon welders operate on different principles. AC welders are typically used for welding aluminum and magnesium alloys, while DC welders are better suited for steel and stainless steel due to their smoother welding properties.

Are portable argon welders as effective as stationary ones?

Portable argon welders are designed for on-site jobs that require mobility, while stationary welders are often more powerful and provide better control over the welding process.

What should I consider regarding material specifications when choosing an argon welder?

When selecting an argon welder, ensure it is compatible with the material specifications required for your project. This includes the thickness of the material, the type of metal being welded, and any additional elements like specific grades or alloys.

Is it possible to get a customized argon welder for my business needs?

Many suppliers offer customized support such as ODM or OBM to tailor argon welders to specific business requirements, including custom software and hardware components.

What safety features should I look for when purchasing an argon welder?

Look for safety features like low voltage operation, overcurrent protection, and high-temperature shut-off to ensure safe and reliable operation in all working conditions.

How does the material of an argon welder affect its performance?

The material construction of an argon welder will determine its durability, suitability for different welding tasks, and the overall quality of the welds it produces. High-quality materials are required for heavy-duty welding applications.

Can I use a regular power outlet to operate an argon welder?

Most argon welders require a power source that can deliver the necessary voltage and amperage. Always use a power source that matches the specifications of your argon welder.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4