Introduction to Automatic Bread Lines

The advent of automatic bread lines has revolutionized the baking industry, offering a seamless and efficient approach to bread production. These systems embody the integration of modern technology and engineering excellence, catering to the demands of large-scale production and precision in the creation of various bread types.

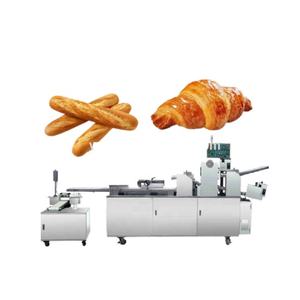

Types and Applications

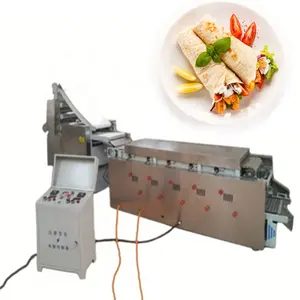

From the automatic line for Arabic bread to the specialized automatic pita bread production line, these automated systems cater to a diverse range of bread-making traditions. Each line is designed to handle specific dough types and baking methods, ensuring that the end product – be it pita, lavash, or any other variety – maintains its authentic taste and texture. The automatic lavash production line and lavash bread automatic line are prime examples of this specialization, tailored to produce the thin, soft flatbreads that are staples in many cuisines.

Features and Materials

An automatic bread line is constructed with durability in mind, utilizing robust materials that withstand the rigors of continuous operation. The integration of advanced sensors and control systems allows for precise ingredient handling and process timing, which are crucial for consistent product quality. The materials used are typically food-grade and resistant to the high-stress environment of baking, ensuring longevity and reliability.

Advantages of Automation in Bread Production

The transition to automation, such as the use of a pita bread automatic line, offers numerous advantages. Efficiency is significantly enhanced, with the capability to produce large volumes of bread in a reduced timeframe. This efficiency does not compromise the quality, as the automated processes ensure uniformity and consistency in every batch. Additionally, the energy-efficient design of these lines can contribute to lower operational costs.

Operational Considerations

While the operational prowess of an automatic bread line is evident, it is also designed with ease of maintenance in mind. The availability of spare parts and the simplicity of repair work ensure that downtime is minimized. Furthermore, manufacturers provide comprehensive user guidelines to facilitate safe and optimal operations, although the specifics of on-field installation and operation can vary and should be discussed with the supplier.

Conclusion

In conclusion, the array of automatic bread lines available caters to a multitude of bread-making traditions and scales of operation. These lines represent a significant leap forward in baking technology, offering an amalgamation of efficiency, quality, and cost-effectiveness. For businesses looking to elevate their bread production capabilities, exploring the options within this category could be a pivotal step.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4