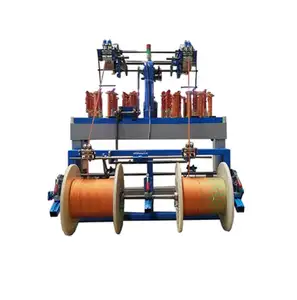

A braiding machine is a specialized industrial apparatus designed for the intricate process of intertwining multiple strands of material to create a cohesive and robust structure. This machinery plays a pivotal role in textile and rope production, providing a systematic and efficient means of achieving complex braided patterns.

Braiding machines accommodate a diverse range of materials, including natural fibers such as cotton and hemp, as well as synthetic materials like nylon and polyester. The choice of material depends on the intended use and the desired characteristics of the final braided product.

Different types of braiding machines

There are various types of braiding machines, each tailored to specific applications. The rope braiding machine is specifically engineered for the production of ropes, employing a systematic process of intertwining multiple strands to create strong and durable ropes. Another variant is the 4-strand braiding machine, designed to handle four strands simultaneously, offering versatility in creating intricate braided patterns. For more complex applications, the industrial braiding machine can handle a broader range of materials and configurations. A notable subtype is the 16-carrier braiding machine, distinguished by its ability to handle 16 strands concurrently, resulting in intricate and dense braids.

Uses of braiding machines

Braiding machines play a crucial role in the manufacturing process of a wide array of products. They are integral to the production of ropes used in maritime environments, reinforcing cables for infrastructure, and intricate textiles for high-end fashion. The application spectrum underscores the adaptability and indispensability of braiding machines across different industries, ranging from textile manufacturing and construction to aerospace. For example, the rope braiding machine is crucial for producing sturdy ropes utilized in marine, rescue, and industrial settings. Meanwhile, the 4-strand braiding machine is employed for applications where a balance between complexity and efficiency is required, such as in the creation of textile patterns with moderate intricacy.

Advantages and disadvantages of braiding machines

The benefits of braiding machines include increased production efficiency, precise pattern control, and the ability to create durable products. Industrial braiding machines offer several advantages that contribute to their widespread use in various industries. One primary advantage is the increased efficiency they bring to the production process. These machines can rapidly intertwine multiple strands of material, enhancing productivity and reducing labor costs. Precision in pattern control is another key benefit, ensuring consistent and intricate designs in textiles, cables, and ropes. The versatility of industrial braiding machines is notable, as they can handle a diverse range of materials, from natural fibers to synthetic polymers, making them adaptable to different applications.

However, alongside these advantages, there are notable disadvantages. The initial investment cost for acquiring a braiding machine, particularly high-capacity or specialized models, can be substantial. Additionally, skilled operators are required to ensure optimal performance, adding to the overall operational expenses. Maintenance demands attention to prevent breakdowns, and not all businesses may have the resources for regular upkeep.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4