Introduction to Brake Lathe Parts

Brake lathe parts are essential components in the automotive maintenance industry, specifically designed for resurfacing brake drums and rotors. These parts play a crucial role in the functionality of a brake lathe, a machine used to correct thickness variations and surface irregularities, ensuring the safety and efficiency of a vehicle's braking system.

Types and Applications

The variety of brake lathe parts caters to different models, including the ammco brake lathe, accuturn brake lathe, and fmc brake lathe. Each part is tailored to meet the specific needs of various lathe models, whether it's for a brake disc lathe or a brake drum lathe. These parts are integral to machines used for resurfacing operations, such as the brake disc turning machine and the brake rotor turning machine, which are widely utilized in automotive repair shops to maintain the optimal condition of brake systems.

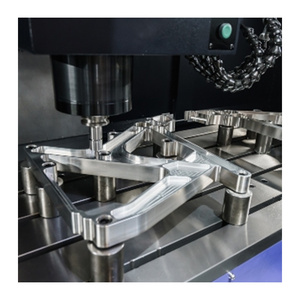

Features and Materials

Constructed from durable materials like metal and FRP, brake lathe parts are built to withstand the rigors of heavy-duty use. The components of a brake rotor lathe machine are designed for resilience, ensuring they can sustain repeated use over time. These parts often include enhancements like a centralized automatic lubrication guide, which minimizes heat distortion and promotes machine stability.

Advantages of Precision Components

Precision is paramount when it comes to brake lathe parts, as the accuracy of machining directly affects the performance of the brake system. The parts available for machines such as the ammco 4000e brake lathe and the ammco brake lathe 4000b are engineered to deliver consistent results. This precision allows for operations like drilling, reaming, tapping, and knurling to be executed with exactitude, contributing to the overall safety and longevity of the vehicle's brake system.

Technological Integration

Modern brake lathe parts are imbued with advanced technology, including low noise generation for a more pleasant work environment. The integration of such technology ensures that machines like the brake disk skimming machine operate not only with high efficiency but also with reduced operational noise, creating a better experience for technicians and workers.

Choosing the Right Parts

Selecting the appropriate brake lathe parts requires consideration of the specific lathe model and the intended use. With a range of designs, shapes, and sizes, these parts must be chosen with precision to match the requirements of the task at hand. While Alibaba.com serves as a marketplace to connect buyers with a plethora of suppliers offering these components, it is crucial to assess the compatibility and specifications of the parts to ensure they meet the necessary standards for each unique application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4