Exploring the Versatility of Chop Cutting Machines

Chop cutting machines are essential tools in various industries, designed to meet the diverse needs of cutting operations. These machines, including chop saw machine and miter saw machine, are engineered to provide precision and efficiency in cutting tasks. Whether it's for culinary purposes or industrial applications, understanding the capabilities and features of these machines is crucial for selecting the right equipment.

Materials and Durability

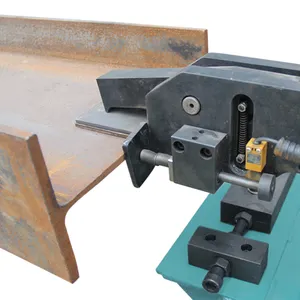

The construction of a chop cutting machine is a key factor in its performance and longevity. Common materials used in the manufacturing of these machines include cast iron, stainless steel, and plastic. Cast iron and stainless steel are preferred for their durability and suitability for heavy-duty tasks, such as with a cold cutting chop saw or a metal cutting mitre saw. These robust materials ensure that the machine can withstand the rigors of frequent use, especially in industrial settings where a cold cut metal saw is indispensable.

Functionality and Applications

Beyond slicing potatoes, a versatile chop cutting machine can handle a variety of materials. For instance, a mitre saw for aluminum or an aluminium cutting mitre saw is specifically designed to tackle non-ferrous metals with precision. Similarly, a mitre saw wood variant is tailored for carpentry, enabling intricate cuts for woodworking projects. The design of the blade and the machine's power determine its suitability for different materials, from vegetables to metals.

Features and Ease of Use

Ease of cleaning and user-friendliness are paramount when considering a chop cutting machine. Models that can be disassembled and are dishwasher-safe offer convenience for culinary uses. In contrast, industrial chop cutting machines, like a chop saw cutting machine, prioritize blade sharpness and durability for effective slicing. The design and size of the blade also influence the types of cuts, which is crucial for tasks requiring a double miter saw or a mitre cut circular saw.

Choosing the Right Chop Cutting Machine

Selecting the appropriate chop cutting machine involves considering the specific needs of your project or business. For heavy-duty metal cutting, a dewalt cutting machine 14 inch might be appropriate, offering power and precision. For those in the construction industry, a mitre saw aluminum cutting machine could be the tool of choice for its ability to handle sturdy materials. It's essential to assess the machine's compatibility with the intended materials and the desired outcome of the cutting process.

Conclusion

A chop cutting machine is a versatile and indispensable tool in both culinary and industrial contexts. When selecting a machine, it's important to consider the material, functionality, features, and ease of use to ensure it meets the specific requirements of the task at hand. With a range of machines available, from the aluminium mitre saw to the chop saw cutter machine, there is a solution for every cutting need.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4