Transparent plastic wall panels epitomize a fusion of robustness, optical purity, and enduring quality as a building material. Employed across diverse commercial and industrial landscapes, these panels deliver a contemporary aesthetic while fulfilling practical roles. The key product, transparent plastic wall panels, spans a gamut of specialized offerings, each with distinct attributes and advantages.

Assortment and Attributes of Transparent Plastic Wall Panels

The array of transparent plastic wall panels encompasses various iterations, each engineered for distinct uses and advantages. Twinwall polycarbonate panels are prized for their featherweight yet sturdy composition, striking an optimal balance between thermal insulation and light admittance. Clear PVC panels are recognized for their cost-effectiveness and adaptability, favored in scenarios where budget is a key concern. Double walled polycarbonate sheets are noted for their exceptional impact resilience and thermal retention, suited to more rigorous settings. The 10mm twinwall polycarbonate variant is in high demand for commercial roofing, courtesy of its superior stiffness and insulative qualities, whereas 4mm twinwall polycarbonate sheets are apt for indoor uses like ornamental dividers, where installation simplicity and weight are crucial. Moreover, the ready availability of twin wall polycarbonate sheets near me enables local enterprises to promptly acquire these materials for their construction projects.

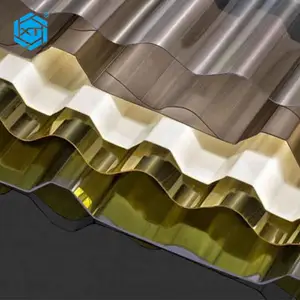

Construction and Merits of Twin Wall Polycarbonate Panels

The clever architecture of twin wall polycarbonate panels is manifested in their dual-layered structure, connecting two polycarbonate sheets with a central layer. This design not only bestows remarkable sturdiness but also forms an insulating air pocket, markedly boosting thermal efficiency. The panels' build is further refined with UV-inhibiting coatings and hermetically sealed edges to bar moisture and contaminants, preserving transparency and functionality over time. Their interlocking configuration simplifies installation and augments structural solidity post-assembly, rendering them a steadfast option for enduring use.

Substances and Processing Offerings

The choice of materials for transparent plastic wall panels is critical to their performance. Polycarbonate is selected for its unparalleled impact fortitude and visual clarity, while PVC provides a harmony of chemical resilience and malleability. Employing 100% virgin material guarantees panels of the utmost caliber, devoid of imperfections that might weaken their structural integrity or aesthetic. These substances are amenable to various processing services, such as bending, precision cutting, and welding, permitting extensive personalization to satisfy the unique specifications of diverse projects. Available surface finishes, from smooth to high gloss, accommodate design preferences while preserving the material's intrinsic advantages.

Commercial Utilization and Applications

Transparent plastic wall panels have permeated a vast range of business applications, transforming spatial design and utility. Within the construction realm, they are pivotal for crafting energy-efficient edifices, serving as skylights, roofing, and glazing that permit natural illumination while upholding thermal comfort. Retail environments gain from their incorporation in showcases and dividers, offering unobstructed product visibility without sacrificing security. In agriculture, polycarbonate clear multiwall roof panels are fundamental to greenhouse construction, optimizing light penetration for plant cultivation while insulating against inclement weather. These uses highlight the panels' capacity to add value to businesses by elevating the functionality and aesthetics of their premises.

Utility and Advantages

The principal role of transparent plastic wall panels is to act as a resilient, see-through partition capable of withstanding substantial impacts and harsh climatic conditions. They are crafted to fulfill diverse functions, such as sound dampening, UV shielding, and thermal insulation. These capabilities are especially vital in venues like airports, where noise mitigation is crucial, or in sports complexes, where safety and unobstructed views are key. The panels' proficiency in preserving transparency while offering protection and insulation renders them an essential component in contemporary building practices.

Distinctive Qualities and Selling Propositions

Notable qualities of transparent plastic wall panels include their superior light permeability, resistance to UV deterioration, and their ability to withstand extreme temperatures without deforming or fading. These traits set them apart from conventional materials such as glass, providing a more secure and durable alternative. Moreover, the competitive twin wall polycarbonate sheet price makes these panels an economical choice for myriad uses, without compromising on quality or efficacy. Their lightweight nature also leads to lower transportation and handling expenses, further bolstering their attractiveness to purchasers.

Advantages and Positive Impacts

Employing transparent plastic wall panels yields numerous benefits, tackling prevalent challenges in construction and design. They facilitate the creation of secure, insulated, and well-lit spaces in commercial and industrial structures. The panels' insulative properties contribute to energy conservation, while their impact resistance ensures durability and diminishes the frequency of replacements. Their low-maintenance and easy-to-clean nature adds to the user-friendly appeal of these panels, making them a pragmatic selection for various environments.

Installation Guidelines for Transparent Plastic Wall Panels

Installing transparent plastic wall panels is a straightforward yet meticulous process that is essential for ensuring longevity and optimal performance. Precise measurement and tailored cutting are the initial steps, succeeded by accommodating thermal expansion. The panels must be securely encased and sealed at the joints to avert water penetration. For those in search of twin wall polycarbonate panels near me, local vendors often provide installation services and guidance, guaranteeing that the panels are set up in compliance with regional building standards and climatic factors.

Maintenance and Cleaning Protocols

Upholding the clarity and functionality of transparent plastic wall panels is a straightforward affair. Routine cleansing with gentle detergent and water is generally adequate to preserve their appearance. For more persistent grime or stains, specialized non-abrasive cleaners formulated for polycarbonate should be employed to prevent surface damage. Regular inspections for seal integrity and fastener condition will aid in extending the lifespan of the installation, ensuring sustained performance of the panels.

Are these panels appropriate for high-impact zones?

Indeed, transparent plastic wall panels, particularly those crafted from polycarbonate, are engineered for high-impact areas. They boast a strength up to 200 times that of glass, rendering them virtually indestructible and apt for settings where safety and endurance are of the essence.

Can these panels be utilized for thermal insulation?

Certainly. Double walled polycarbonate sheets and twinwall polycarbonate excel in thermal insulation. Their multilayered construction captures air within the walls, forming a thermal barrier that aids in maintaining consistent interior temperatures, which is beneficial for energy efficiency.

What customization options are accessible?

Customizability stands as one of the prime benefits of transparent plastic wall panels. They can be tailored to specific dimensions, bent, and even welded to conform to particular design needs. With thickness options ranging from 4mm twinwall polycarbonate sheet to 10mm twinwall polycarbonate, there are variants to suit diverse applications, and surface finishes can be customized to augment the aesthetic appeal of any project.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4