CNC Woodworking Machines: An Overview

CNC woodworking machines stand as a cornerstone in modern carpentry, woodworking, and furniture production. These computer-controlled systems offer precision and efficiency, revolutionizing the way wood is shaped and designed. From intricate carvings to robust furniture components, CNC routers facilitate complex and repetitive tasks with ease.

Types and Applications

The versatility of CNC routers is evident in their various types and applications. Industrial-grade CNC machines cater to high-volume production, ideal for manufacturing furniture, decorative frames, and wooden toys. On the other hand, smaller workshops might utilize handheld devices for detailed craftsmanship or portable routers for on-site adjustments. The application spectrum ranges from creating detailed carvings and joinery to executing full-scale architectural millwork.

Features and Materials

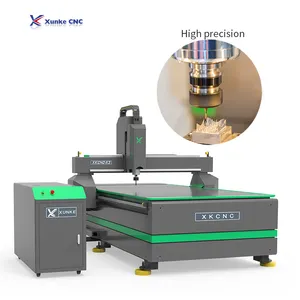

CNC woodworking equipment is designed to handle a wide array of materials, including hardwood, softwood, particleboard, and plastic composites. Key features to consider include the power rating, cutting precision, and the machine's overall footprint. The construction of these machines often involves robust materials like steel and aluminum, ensuring durability and consistent performance.

Advantages of CNC Woodworking

The adoption of CNC technology in woodworking brings numerous advantages. Enhanced precision and repeatability stand out, allowing for the production of identical pieces in succession. Efficiency is another significant benefit, as CNC machines reduce waste and increase the speed of production. Furthermore, the automation of complex tasks minimizes the need for skilled manual labor, which can be redirected to other areas of the production process.

Choosing the Right Machine

Selecting the appropriate CNC wood router involves considering the specific needs of a project or production line. Factors such as the size of the material being worked on, the complexity of the designs, and the desired output rate are crucial. Prospective buyers can filter through a comprehensive selection to find a machine that aligns with their operational requirements, without the influence of brand bias.

Integration in Modern Woodworking

The integration of CNC machines in woodworking is a testament to the industry's evolution. These machines have become indispensable in educational settings for training purposes, in small businesses for product diversification, and in large-scale operations for mass production. The adaptability of CNC machinery to various production scales makes it a valuable asset in any woodworking context.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4