Introduction to Copper Machine Screws

Copper machine screws are integral components in various industrial and construction applications. These screws are known for their electrical conductivity, corrosion resistance, and antimicrobial properties, making them a preferred choice for electrical projects and environments requiring hygienic conditions. This category encompasses a wide range of screws, each designed to meet specific requirements in fastening and assembly processes.

Types and Applications

The versatility of copper machine screws is evident in their various types, such as flat head, pan head, and round head screws, each serving a unique purpose. Flat head screws are typically used in countersunk holes, while pan head screws offer excellent grip for driver tools. Round head screws are selected for their aesthetics and are commonly used in decorative applications. These screws are employed in electrical equipment, woodworking, and even in the production of musical instruments, where precision and durability are paramount.

Features and Materials

Copper machine screws are crafted from high-grade copper alloys, ensuring tensile strength and resistance to wear. The material composition includes elements like zinc, tin, or aluminum to enhance specific properties, such as strength or resistance to environmental factors. Features like thread design and screw length are tailored to the intended application, providing a secure and reliable hold in various substrates.

Advantages of Copper Machine Screws

The advantages of using copper machine screws are numerous. Their natural resistance to corrosion makes them suitable for use in outdoor environments and in applications exposed to water or chemicals. The thermal conductivity of copper also allows these screws to be used in applications where heat dissipation is necessary. Additionally, the aesthetic appeal of copper adds a touch of elegance to exposed fastenings, which is often sought after in architectural and interior design.

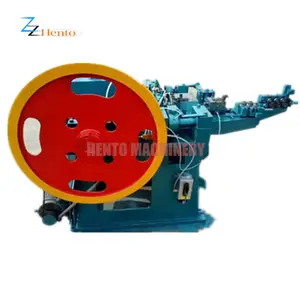

Thread Rolling Machines for Copper Screws

Thread rolling machines are essential for producing high-precision threads on copper machine screws. These machines utilize die-plates to form threads, ensuring consistency and accuracy. With the capability to accommodate various molds, thread rolling machines can produce screws with unique shapes and threading patterns, catering to specialized requirements. The integration of variable speed settings allows operators to control the thread rolling process, optimizing production efficiency.

Choosing the Right Copper Machine Screw

Selecting the appropriate copper machine screw for your project involves considering factors such as the screw's head type, length, diameter, and thread pitch. It is crucial to match these specifications with the material and application to ensure a secure fit and optimal performance. For those seeking to streamline their production, automatic thread rolling machines available on Alibaba.com offer a range of configurations to suit different operational needs, from semi-automatic to fully automatic systems.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4