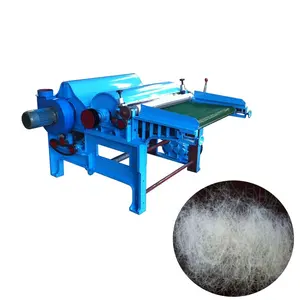

Understanding Cotton Rolling Machines

Cotton rolling machines are essential in the textile industry, designed to process various fibers into a carded form ready for the next stage of production. These machines are categorized mainly by their compatibility with different fiber lengths and their carding mechanisms, such as flats and roller cards. Flat carding machines are typically used for short-staple chemical fibers, ensuring precision and care in handling delicate materials. In contrast, roller carding machines are more suited for longer chemical fibers, providing the necessary carding action to align and prepare the fibers for spinning.

Types and Applications

The versatility of a cotton carding machine is evident in its ability to handle a variety of materials. Each type of machine is engineered to meet specific production needs, whether for lightweight fabrics or more robust textile products. The application of these machines extends beyond just cotton processing; they are also adept at preparing wool, synthetic fibers, and blends for the textile industry.

Features and Material Handling

A key feature of the cotton processing machine is its material feeding technique. For instance, cotton is introduced to flats in a consistent layer, a process facilitated by scutching machines. Conversely, roller-card machines utilize a weighing device to ensure equal portions of fiber are carded at regular intervals. This precise material handling is crucial for maintaining a uniform thickness in the carded output, a vital quality parameter in textile manufacturing.

Machine Specifications and Considerations

When selecting a cotton fiber processing machine, several factors must be taken into account. The size of the machine is paramount; it must fit within the designated space without disrupting the workflow. Additionally, the type of material to be processed should guide the choice of machine, as different fibers require different carding mechanisms. The longevity of the machine is also a consideration, with the availability of spare parts being a practical concern for continuous operation. Lastly, the warranty offered is an important factor, providing buyers with assurance against potential issues within a specified timeframe.

Advantages of Modern Cotton Rolling Machines

Modern cotton rolling machines offer numerous advantages, including enhanced efficiency and improved fiber quality. These machines are designed to minimize waste and maximize output, ensuring that the carding process is both cost-effective and environmentally friendly. The precision with which these machines operate also results in a higher quality carded product, which is crucial for the subsequent stages of textile production.

Choosing the Right Machine on Alibaba.com

For businesses in search of a reliable cotton rolling machine, Alibaba.com presents a comprehensive collection of machines to suit various needs and preferences. The platform facilitates easy comparison of features and specifications, allowing buyers to make informed decisions without the pressure of sales pitches. With a user-friendly interface, Alibaba.com simplifies the procurement process, enabling buyers to place orders efficiently and with confidence in the product's suitability for their requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4