A diamond sharpening stone is used for sharpening and honing blades and cutting tools. It has a flat surface with diamond particles bonded to a metal plate. Diamond sharpening stones are versatile and can be used to sharpen a wide range of cutting tools, including kitchen knives, scissors, chisels, and gardening tools.

The types of diamond sharpening stones

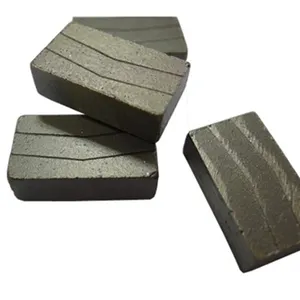

There are several different types of diamond sharpening stones. The single-sided diamond sharpening stones have diamond particles on only one side and are typically used for grinding and polishing the cutting edge of tools. They can come in different grit sizes to accommodate various sharpening needs. The double-sided diamond sharpening stones have diamond particles on both sides, with one side being coarse for repairing dull blades and the other for sharpening and polishing the cutting edge of tools. The round diamond sharpening stones are cylindrical. They are suitable for grinding and polishing curved blades and other circular cutting tools. They have a rounded surface that facilitates grinding on curved edges.

Pocket diamond sharpening stones are small and portable, designed to fit in a pocket or be carried on the go. They are typically suitable for quick repairs and sharpening of cutting edges. Chisel diamond sharpening stones are designed specifically for sharpening chisels and similar woodworking tools. They have flat surfaces with diamond particles bonded to the metal base, providing an abrasive surface for effectively sharpening chisels. Monocrystalline diamond sharpening stones are made using monocrystalline diamonds. Monocrystalline diamonds are grown as single crystals, resulting in a uniform and consistent structure. The type of diamond is known for its high hardness and durability, making it a good choice for sharpening stones.

The usage methods of diamond sharpening stones

Here are some steps to use diamond sharpening stones for sharpening tools. Prepare the sharpening stone: Place the diamond sharpening stone on a stable surface, such as a workbench or table. Ensure the stone is secure and won't slip or move during sharpening. Wet the stone: Use water or honing oil to wet the surface of the sharpening stone. It helps to lubricate the sharpening process, prevent overheating, and reduce the accumulation of debris. Select the proper angle: Choose the appropriate sharpening angle depending on the type and purpose of the tool. Generally, larger angles are suitable for initial grinding, while smaller angles are used for fine sharpening and polishing.

Start sharpening: Gently place the cutting edge of the tool on the diamond sharpening stone and maintain a consistent angle. Apply moderate pressure and slide the tool back and forth along the surface of the stone. Be mindful of maintaining a consistent sharpening direction to avoid damaging the tool. Even sharpening: Depending on the needs, alternate between different areas of the sharpening stone to ensure overall even sharpening of the tool. Regularly check the cutting edge of the tool to assess the sharpening progress. Adjust the angle: If users need to change the cutting angle of the tool, make slight adjustments to the sharpening angle as necessary. Be cautious when adjusting the angle to avoid damaging the tool. Clean the tool and stone: After sharpening, use water and a brush or cloth to clean the tool and diamond sharpening stone, removing debris and residue. Ensure a thorough cleaning and allow them to dry completely.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4