What are Die Casting Machines

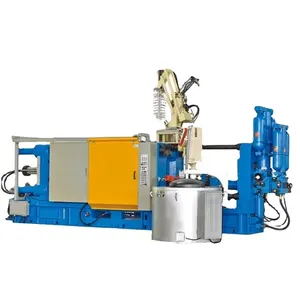

Die casting machines are specialized pieces of equipment used in the manufacturing industry to produce metal parts with intricate shapes and fine details. This machinery is suitable for high-volume production of metal products, making it essential for industries such as automotive, consumer electronics, and household appliances. Die casting works on the principle of injecting molten metal under high pressure into a mold cavity, where it solidifies into the desired shape.

The process begins with the melting of the metal, which can include aluminum, zinc, magnesium, or copper alloys. Once liquefied, the metal is rapidly injected into a steel die (a permanent mold) under high pressure, ranging from a few hundred to several thousand pounds per square inch. The high pressure ensures that the metal flows into all areas of the die, capturing the complex geometries and surface textures designed into the mold. After a brief cooling period, the die opens to eject the solidified part, which is then finished as required.

Die casting machines are designed for efficiency and precision. They cater to businesses that require consistent quality and mass production capabilities. The machines can be automated to increase productivity and minimize labor costs while ensuring that each part meets stringent specifications. Die casting is also environmentally friendly because it allows for high material utilization rates and recycling of scrap metal.

Types of Die Casting Machines

Die casting machines come in various types to accommodate different metals and applications:

Hot Chamber Die Casting Machine: These machines are commonly used for metals with lower melting points, such as zinc, magnesium, and lead alloys. The machine's chamber is immersed in the molten metal, allowing for quick cycles since it does not need to heat up significantly between shots. This makes hot chamber die casting ideal for producing small components like zippers, buckles, and keys in large quantities.

Cold Chamber Die Casting Machine: Suited for metals with high melting points such as aluminum and brass alloys, cold chamber die casting machines require manual or automatic ladling of molten metal into the injection system. These machines can handle larger parts and maintain higher structural integrity due to their ability to work with higher-melting-point metals.

Gravity Die Casting Machine: Also known as permanent mold casting machines, these utilize gravity to fill the die rather than high-pressure injection. This method is slower but can yield parts with better mechanical properties and surface finish. It's suitable for medium to large components where strength and aesthetic quality are priorities.

Each type has its specific use cases based on the properties of the metals being cast and the detailed requirements of the final product.

How to choose Die Casting Machines

Selecting an appropriate die casting machine involves several considerations:

- Metal Type: Identify what type of metal you'll be working with; this will determine if you need a hot chamber or cold chamber machine.

- Part Size and Complexity: Analyze the size and complexity of parts you plan to produce. Larger parts with intricate details may require cold chamber machines with higher clamping forces.

- Production Volume: Consider your production requirements. High-volume runs will benefit from automation features that increase speed and consistency.

- Precision Requirements: Review the precision level needed for your parts; some machines offer higher accuracy than others.

- Energy Efficiency: Look for energy-saving features if long-term operational costs are a concern.

- Safety Features: High safety levels are essential for protecting operators; ensure that machines comply with industry standards.

- Service Life and Maintenance: Evaluate the durability of machines and accessibility of after-sales service options to ensure long-term reliability.

When navigating Alibaba.com's extensive listings for die casting machines, businesses should filter options based on these considerations while also considering key selling points like automation capabilities and energy savings.

Best Die Casting Machines on Alibaba.com

Alibaba.com stands out as an expansive marketplace that connects a global network of suppliers with businesses seeking specialized machinery such as die casting machines. The platform is renowned not only for its diversity in product offerings but also for its commitment to facilitating secure transactions through its Trade Assurance service.

Businesses looking to procure die casting machines will find Alibaba.com's interface conducive to locating an array of options that match their specific industry needs—be it automotive production or consumer electronics manufacturing. With tools enabling communication in local languages and mobile-friendly buying features, Alibaba.com ensures a seamless purchasing experience regardless of one's location or device preference.

Moreover, Alibaba.com's emphasis on verifying supplier credibility assures businesses that they are engaging with trustworthy entities capable of delivering machinery that aligns with their operational demands. Whether a company requires a hot chamber machine for zinc components or a cold chamber system for aluminum products, Alibaba.com offers a platform where they can confidently source machinery suited to their applications without compromising on quality or dependability.

Common FAQs for Die Casting Machines

What is the difference between hot chamber and cold chamber die casting machines?

Hot chamber die casting machines are best for metals with low melting points and fast cycle times, like zinc, magnesium, and lead alloys. Cold chamber machines are used for metals with higher melting points, such as aluminum and brass, and involve manually pouring metal into the injection system.

How do I determine the clamping force required for a die casting machine?

The clamping force required depends on the projected area of the part to be cast and the pressure at which the metal is injected. Larger parts with higher injection pressures will need machines with greater clamping force.

Can die casting machines handle different metals?

Yes, but the type of machine you need will vary depending on the metal. Hot chamber machines are suitable for metals with low melting temperatures, while cold chamber machines are necessary for metals with high melting temperatures.

What are the typical applications of die casting machines?

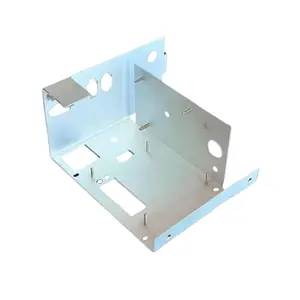

Die casting machines are widely used in automotive, consumer electronics, and household appliances industries to create intricate metal parts like engine components, gearboxes, and electronic housings.

How does die casting ensure dimensional accuracy in produced parts?

Die casting machines inject molten metal into precision-engineered molds under high pressure, which ensures that the metal reaches all parts of the mold and solidifies with high accuracy to match the desired dimensions.

What are some key selling points I should look for in a die casting machine?

When selecting a die casting machine, consider attributes such as automation capabilities, energy efficiency, ease of operation, safety features, long service life, and low maintenance costs.

What after-sales services are typically offered with die casting machines?

Suppliers may offer various after-sales services such as video technical support, online support, on-site engineers for machinery service overseas, and field maintenance and repair services.

How important is energy efficiency in die casting machines?

Energy efficiency is increasingly important to reduce operational costs and environmental impact. Machines with energy-saving features can significantly lower electricity consumption over their lifetime.

What is the importance of machine rigidity in die casting?

High rigidity in a die casting machine ensures stable operation and precise alignment of the machine components during the casting process, which is crucial for maintaining part quality and prolonging machine life.

Can I use a die casting machine for different types of products?

Yes, die casting machines are versatile and can be adjusted or equipped with different molds to produce a wide range of products across various industries.

What should I consider regarding local service locations when purchasing a die casting machine?

Consider sourcing a machine from a supplier who can provide service in your region to ensure timely maintenance and repair services that minimize downtime.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4