Introduction to Felt Making Machines

Felt making machines are integral components in the textile industry, specifically designed for the production of nonwoven fabrics. Utilizing advanced technology, these machines streamline the felt production process, enhancing efficiency and output. The felt making machine China market offers a diverse range of models to cater to various production needs, ensuring that every facility, regardless of size, can find a suitable solution.

Types and Applications

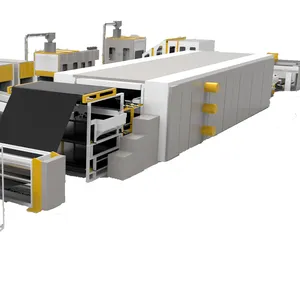

The array of felt making machines includes several types, each tailored for different production scales and requirements. From compact units ideal for small-scale operations to industrial-grade machines for mass production, the versatility of these machines meets a broad spectrum of applications. They are widely used in the automotive, furniture, and insulation industries, among others, to produce high-grade felt products.

Operational Features

These machines boast sophisticated features that promote ease of use and consistent quality. With automated control systems, operators can precisely adjust production parameters, ensuring uniformity in the size and thickness of the felt produced. The operational efficiency of felt making equipment is a testament to the innovation embedded in their design, allowing for rapid production without compromising on the quality of the output.

Material and Construction Advantages

Constructed with durability in mind, felt making machinery is built using robust materials that endure the rigors of continuous operation. The sturdy components contribute to the longevity of the machines, making them a reliable choice for businesses aiming to maintain continuous production. Additionally, the construction of these machines takes into account the dynamic forces they encounter, further enhancing their durability.

Safety and Efficiency

Safety is paramount in the operation of any industrial machinery. Felt making machines from China are equipped with safety features that minimize the risk of accidents, ensuring operator protection during use. Efficiency is not compromised for safety, however, as these machines maintain high production speeds while adhering to safety standards.

Choosing the Right Machine

Selecting the appropriate felt making machine is crucial for optimizing production. The vast selection available in the Chinese market allows for careful consideration of machine specifications against production requirements. While the choice of machine will depend on individual production needs, the common denominator across all machines is their ability to bolster productivity and maintain consistent output quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4