Understanding Fittings in Piping Systems

Fittings are integral components of piping systems, serving as the connective elements that join pipe sections, regulate flow, or change the direction of the fluid conveyance. These crucial parts come in various shapes, sizes, and materials, each tailored to specific applications and fluid types. This introduction delves into the diverse world of fittings, exploring their types, applications, and material-specific advantages.

Types and Applications of Fittings

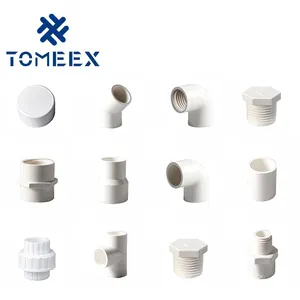

The application of fittings spans across both commercial and residential domains, ensuring the integrity and functionality of piping systems. Common types include elbows, tees, couplings, and flanges, each serving a unique purpose. Elbows are used to change the direction of flow, tees for branching off, couplings for extending or repairing, and flanges for connecting pipes to other components. Specialized fittings like P-traps in plumbing prevent odor by trapping water, while pipe caps are used to seal the end of a pipe to halt fluid flow.

Material Considerations for Fittings

The choice of material for fittings is dictated by the nature of the fluid transported. PVC fittings, known for their smooth inner walls, reduce flow resistance and are favored for their lightweight and cost-effectiveness. They are suitable for a variety of non-corrosive applications. Conversely, copper fittings are chosen for their corrosion resistance and are particularly reliable for underground plumbing due to their durability against external factors.

Features of Fittings

Each fitting material comes with inherent features that make them suitable for specific conditions. For instance, the smooth surface of PVC reduces the risk of clogs and eases maintenance. Copper fittings, on the other hand, offer a robust solution for environments where corrosion or temperature extremes are a concern. The selection of fittings must align with the operational demands of the piping system, such as pressure ratings and chemical compatibility.

Advantages of Proper Fitting Selection

Selecting the appropriate fittings for a piping system is not merely a matter of compatibility but also contributes to the longevity and efficiency of the system. Properly chosen fittings minimize leak points, maintain pressure integrity, and ensure the safe transport of fluids. The advantages of a well-designed system with the right fittings include reduced maintenance costs, improved system performance, and extended service life.

Conclusion

In conclusion, the role of fittings in piping systems is indispensable. With a comprehensive range of types and materials, they cater to various applications, ensuring the seamless operation of fluid transport systems. The selection process must consider the specific requirements of the system, including the type of fluid, pressure conditions, and environmental factors. By understanding the characteristics and advantages of different fittings, one can ensure the integrity and efficiency of any piping network.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4