Introduction to Floor Moulding Machines

Floor moulding machines are essential in the manufacturing sector, providing the means to shape and create detailed profiles for flooring trims and baseboards. These machines cater to a variety of production needs, from small-scale operations to large industrial tasks. With a focus on efficiency and precision, floor moulding machines are a cornerstone in the production of flooring accessories.

Types and Applications

The versatility of floor moulding machines is evident in the array of types available, each suited to specific tasks and materials. From simple bar rail moulds to intricate baseboard patterns, these machines are designed to accommodate a wide range of designs. Applications extend across residential and commercial construction, where the demand for both aesthetic appeal and functionality is high.

Features and Materials

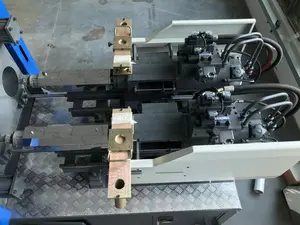

Injection moulding machines and iron moulds are among the common types used in the creation of floor mouldings. The choice of material for the moulds includes various metals and composites, each selected for its durability and performance under the pressures of production. Features of these machines often include advanced control systems for precision and consistency in production runs.

Advantages of Modern Moulding Machinery

The adoption of modern mould fabrication services offers numerous advantages. Enhanced speed and accuracy in production lead to increased efficiency and reduced waste. Additionally, the ability to standardize components such as lift bars and clamp slots contributes to a streamlined process, especially when managing multiple product lines.

Optimizing Production with Floor Moulding Machines

Optimization is key in utilizing floor moulding machines effectively. Suppliers on Alibaba.com provide extensive information to assist in selecting the right machine that aligns with production goals. Standardization of mould components is a strategic approach to minimize future production costs and simplify the manufacturing process.

Choosing the Right Machine

Selecting the appropriate floor moulding machine involves evaluating design requirements, material compatibility, and production capacity. Alibaba.com hosts a diverse range of suppliers, each offering machines with different capabilities. This variety ensures that businesses can find a machine that meets their specific moulding needs without compromising on the quality of the finished product.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4