Introduction to FRP Winding Machines

Fiberglass Reinforced Plastic (FRP) winding machines are specialized equipment designed for the production of FRP composites, commonly used in various industries. These machines facilitate the process of winding resin-impregnated fiber strands to create durable composite materials. The technology behind FRP winding machines is engineered to ensure consistent quality and efficiency in the manufacturing process.

Types and Applications

The versatility of FRP winding machines allows for their application in numerous sectors. From the creation of lightweight automotive components to sturdy pipes for the petrochemical industry, these machines are integral in producing items that benefit from the strength-to-weight ratio of FRP. In the utility sector, they are used to manufacture poles and in construction for creating supportive structures.

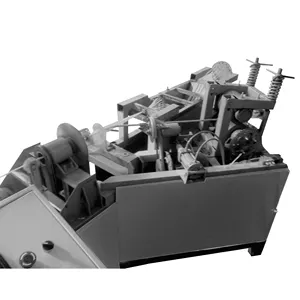

Operational Features

FRP winding machines are designed with user-friendly interfaces, making them accessible to operators of varying skill levels. The automated nature of these machines allows for precise control over production variables, ensuring uniformity in the final product. Advanced models can handle different viscosities and materials, from thick resins to more fluid substances, expanding their use across different production lines.

Material and Design Advantages

The construction of FRP winding machines involves robust materials that withstand the demands of continuous operation. The design of these machines often includes features that minimize waste and streamline the production process. This not only enhances the sustainability of operations but also contributes to the cost-effectiveness of the manufacturing cycle.

Efficiency and Cost-Effectiveness

Incorporating an FRP winding machine into a production line can significantly elevate efficiency. The automation minimizes the need for manual intervention, reducing labor costs and the potential for human error. The precision of these machines ensures that materials are used optimally, which, in conjunction with energy-efficient operation, can lead to reduced operational costs.

Choosing the Right Machine

Selecting the appropriate FRP winding machine involves considering the specific requirements of the production job. Factors such as the size of the workspace, the type of FRP composites to be produced, and the desired production capacity are crucial. Alibaba.com hosts a variety of suppliers offering machines with different specifications to cater to a broad range of manufacturing needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4