Introduction to Gold Smelting Furnaces

The process of extracting and refining gold from its ores is a complex and crucial aspect of the precious metals industry. A gold smelting furnace is at the heart of this process, providing the necessary heat to melt gold and other metals, facilitating the purification and alloy creation. These furnaces vary in size, capacity, and technology, catering to different scales of operations, from small gold melting furnaces suitable for boutique jewelers to industrial-sized equipment for larger operations.

Types and Applications

There is a diverse range of furnaces for gold melting, each designed to meet specific needs. The induction gold melting furnace is a popular choice for its efficiency and the precise control it offers. Meanwhile, electric gold melting furnaces are known for their consistent performance and are commonly used in both industrial settings and by those requiring a home gold smelter. The application of these furnaces spans from jewelry manufacturing to metalworking industries where the transformation of raw gold into usable forms is required.

Features and Materials

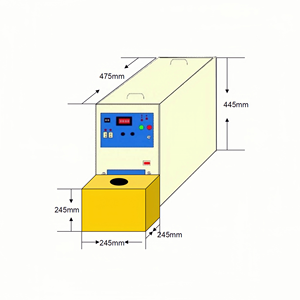

A typical gold smelting machine incorporates advanced features to ensure effective melting and safety. These machines are constructed from robust materials capable of withstanding high temperatures, usually ranging from 1,750 to 2,100 degrees Celsius. The melting pots, often made from high-grade refractory materials, are designed to tilt, some up to 95 degrees, to facilitate the easy pouring of molten metal.

Advantages of Modern Gold Smelting Equipment

Modern gold smelting equipment boasts numerous advantages, such as rapid melting speeds, which can vary from 40 to 60 minutes depending on the metal and furnace type. The integration of PLC systems for operation and large capacitor banks to stabilize current exemplifies the technological advancements in these machines. Additionally, water-cooling systems are a standard feature to manage the high operational temperatures.

Innovative Technologies in Gold Melting

Innovation in the field has led to the development of gold melting gas bhatti and electric gold melting machines, which offer cleaner and more energy-efficient options. The use of hydraulic systems to provide tilting force and electrical induction systems for heating are examples of how these machines have evolved to improve the gold melting process.

Choosing the Right Gold Smelting Furnace

Selecting the appropriate jewellery melting furnace involves considering the metal types, melting speed, temperature range, and the size of the operations. Alibaba.com presents a comprehensive collection of gold melting solutions, from small gold melting machines to larger industrial models, all designed to meet the diverse needs of the metal processing industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4