Introduction to Leather Bag Cutting Machines

Leather bag cutting machines are specialized equipment designed for precision cutting of leather materials to create various bag designs. These machines cater to the needs of manufacturers who require efficient and accurate cutting to produce leather bags. With advanced technology, these machines streamline the production process, ensuring consistent quality and increased productivity.

Types and Applications

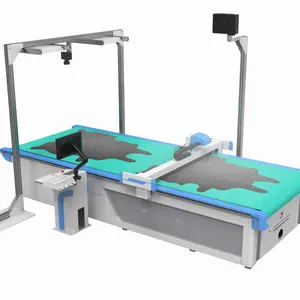

There are various types of leather bag cutting machines, each serving a specific purpose in the production line. From manual die-cutting presses to advanced CNC (Computer Numerical Control) leather cutting systems, the selection caters to different production scales and complexities. These machines are crucial in industries ranging from fashion to luggage manufacturing, where they are employed to cut leather for handbags, backpacks, wallets, and other accessories.

Features and Materials

Leather bag cutting machines are constructed with robust materials to withstand the rigors of leather processing. They come equipped with sharp blades, precise control systems, and durable surfaces to handle various leather types, from soft suede to tougher full-grain hides. Features may include customizable cutting dies, automated feeding systems, and intuitive software that facilitates intricate cuts and patterns, essential for creating a cricut leather purse.

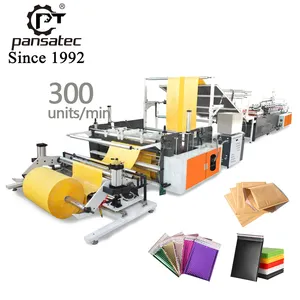

Advantages of Modern Cutting Technology

The modern leather bag cutting machine offers numerous advantages, such as enhanced speed and accuracy, which are paramount in meeting the demands of today's fast-paced production environments. Automation in these machines minimizes material waste and maximizes efficiency, which is particularly beneficial for businesses aiming to scale up their operations. Additionally, the precision of these machines ensures that each cut is consistent, contributing to the overall quality of the finished leather product.

Choosing the Right Machine

Selecting the right leather bag cutting machine involves considering the machine's size, speed, and the specific heat source it utilizes, if applicable. Prospective buyers should assess their production capacity to determine the most suitable machine that aligns with their output requirements. Whether for a small-scale artisanal operation or a large industrial setup, there is a range of machines to suit various production needs. Some machines in the market are highly automated, capable of not just cutting, but also embossing leather with exquisite patterns, enhancing the aesthetic appeal of the final product.

Complementary Equipment and Support

In addition to cutting machines, there is a spectrum of complementary equipment available for the entire leather bag production process. This includes machinery for preparing and tanning hides, as well as devices for the final stages of bag manufacturing. For those looking to add unique touches to their products, machines capable of embossing and printing on leather offer the opportunity to customize designs, providing an edge in a competitive market.

Incorporating a leather bag cutting machine into your production line can significantly enhance the efficiency and quality of your leather goods. With a variety of machines available, it is important to choose one that aligns with your production needs and capacity. For those in the business of creating personalized leather items, a machine that can also handle cricut leather purse projects may be particularly beneficial. As you browse the selection, consider the long-term value that such equipment can bring to your operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4