Introduction to Light Making Machines

The realm of electronics manufacturing is revolutionized by the advent of light making machines, a category that encompasses a variety of apparatus designed to streamline the production of lighting solutions. These machines cater to the assembly and creation of electronic components, including but not limited to LED bulbs, circuit boards, and electronic devices. The led light making machine stands as a pivotal component in this category, facilitating the mass production of LED lighting by automating intricate manufacturing processes.

Types and Applications

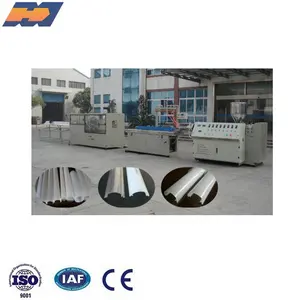

Within this category, there are several types of machinery, each serving a specific function in the production line. From manual led bulb making machines to automatic led bulb making machines, the spectrum ranges to accommodate various scales of operation and technical requirements. These machines are integral in producing a myriad of lighting devices, ensuring that everything from household LED lights to sophisticated electronic motherboards is assembled with precision.

Features and Technical Specifications

A comprehensive led manufacturing machine typically integrates multiple units to cover the entire production process. This includes PCB fabrication, component placement, and soldering. Advanced models boast high-speed pick and place machines, capable of accurately assembling thousands of microchips per hour. Furthermore, these machines are equipped with flux systems to ensure clean soldering by removing oxidation, and transport systems to seamlessly move PCBs through the production line.

Materials and Advantages

The construction of these machines involves robust materials that withstand the rigors of continuous operation. The advantages of utilizing a bulb manufacturing machine are manifold, including increased production efficiency, consistency in product quality, and the ability to handle various PCB sizes through adjustable systems.

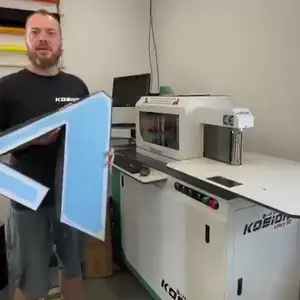

Choosing the Right Machine

Selecting the appropriate led bulb manufacturing machine hinges on understanding the specific needs of a business. Factors such as production volume, space constraints, and technical specifications dictate the suitability of a machine. Whether it's a bulb banane ki machine for small-scale production or a full-scale automated line for large orders, the diversity of machines available ensures a fit for every requirement.

Conclusion

Exploring the range of led bulb banane wali machines on Alibaba.com presents businesses with the opportunity to enhance their manufacturing capabilities. While the platform does not endorse any particular brand or make promises on quality, it provides a comprehensive marketplace to compare different models and find a machine that aligns with your production needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4