Lighting purlins are fundamental components in modern construction, particularly in the creation of support systems for lighting fixtures in large-scale buildings. These structural elements are designed to provide a secure mounting framework for lighting systems, ensuring stability and safety. Lighting purlins are often crafted from materials such as galvanized steel, which offers durability and resistance to corrosion, making them suitable for a variety of environments.

Types and Shapes of Lighting Purlins

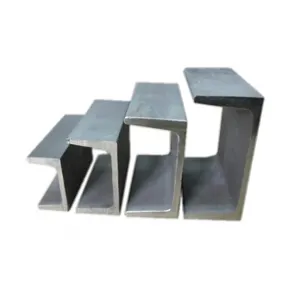

The array of lighting purlins encompasses a range of types, each with unique characteristics to serve different structural requirements. C-shaped purlins are commonly used for their balance of strength and flexibility, allowing for easy attachment of lighting fixtures. U channel purlins offer a deeper channel, which provides more surface area for secure fixture mounting. Z purlins are designed with a shape that offers greater structural support over longer spans, reducing the need for additional bracing. Each type is meticulously engineered to meet specific load-bearing requirements, ensuring that lighting systems are supported safely and securely.

Structure and Composition of Lighting Purlins

The physical structure of lighting purlins is a testament to engineering precision. A typical C-shaped purlin consists of a web, flanges, and lips. The web provides vertical stability, the flanges facilitate attachment to other structural components, and the lips add stiffness to prevent twisting. U and Z purlins are similarly composed but are optimized for different load-bearing scenarios. The integration of these components allows for a modular approach to construction, where purlins can be easily assembled, disassembled, and reconfigured to accommodate various design changes and upgrades.

Materials and Properties

The choice of materials for lighting purlins is critical to their performance. Galvanized steel, favored for its excellent tensile strength and resistance to corrosion, is the most common material. The galvanization process involves coating the steel with a protective layer of zinc, which not only shields the steel from the elements but also extends its lifespan. Carbon steel variants like Q235 and Q235B are selected for their balance of durability and formability, allowing for the creation of purlins that are both strong and easy to install. Mild steel is another option, offering a cost-effective solution while still maintaining sufficient structural integrity for many applications.

Business Usages and Applications

Lighting purlins find their place in a multitude of business settings, from industrial warehouses requiring robust lighting solutions to retail spaces where aesthetics and functionality must coexist. In large commercial complexes, they support heavy-duty lighting systems that illuminate vast areas efficiently. In the agricultural sector, they are used in greenhouses to support grow lights, directly contributing to plant growth and yield. The adaptability of lighting purlins to various business needs makes them invaluable in the construction and design of functional spaces.

Functions and Tasks

The primary function of lighting purlins is to provide a secure mounting point for lighting fixtures. They are designed to bear the weight of these fixtures while resisting the forces of nature, such as wind and seismic activity. Additionally, the perforated design of some purlins allows for easy routing of electrical wiring, simplifying the installation process and maintaining a clean aesthetic.

Features and Capabilities

Lighting purlins boast features that enhance their utility and efficiency. Their modular design allows for rapid assembly and disassembly, which is crucial in project timelines. The availability of various shapes and materials enables customization to specific project needs. Furthermore, the perforation options not only aid in wire management but also reduce the overall weight of the purlins, facilitating easier handling and installation.

Benefits and Improvements

The benefits of using lighting purlins are manifold. They provide a cost-effective solution for lighting support with their long-lasting durability, reducing the need for frequent replacements. The ease of installation and maintenance they offer translates into lower labor costs and less downtime. For businesses, this means uninterrupted operations and enhanced productivity.

How to Use Lighting Purlins

Effective use of lighting purlins involves understanding the layout and requirements of the lighting system. Purlins should be spaced appropriately to evenly distribute the weight of the fixtures and to ensure that the lighting coverage is optimal for the intended area.

How to Choose the Right Lighting Purlins

Selecting the right lighting purlins requires an assessment of the load they will bear, the environmental conditions they will face, and the specific application for which they are intended. Factors such as the type of lighting fixtures, the height of installation, and the nature of the building's use will influence the choice of purlin.

How to Clean and Maintain Lighting Purlins

Cleaning and maintaining lighting purlins is straightforward due to their galvanized surfaces. Regular dusting and inspection for signs of wear or damage ensure their longevity and functionality. Any necessary repairs should be addressed promptly to maintain structural integrity.

How to Install Lighting Purlins

Installation of lighting purlins should follow the manufacturer's guidelines and local building codes. Proper anchoring and alignment are crucial for safety and performance. It is often recommended to engage professional installers to ensure that the purlins are installed correctly.

Target Audience and Needs

The target audience for lighting purlins includes architects, builders, and contractors who require reliable and versatile support systems for lighting. The product meets the needs of these professionals by providing a range of options that can be tailored to the specific demands of each project, whether it be a commercial, industrial, or agricultural setting.

What are the standard dimensions and tolerances for lighting purlins?

Standard dimensions for lighting purlins are determined by the AISI, ASTM, GB, DIN, and JIS standards, which provide guidelines for tolerances, dimensions, and material properties. These standards ensure that the purlins meet the necessary criteria for safety and performance.

Are lighting purlins suitable for outdoor applications?

Yes, lighting purlins are suitable for outdoor applications. Their galvanized steel construction provides excellent protection against weather elements, making them an ideal choice for outdoor lighting support structures.

Can lighting purlins be integrated into existing building designs?

Lighting purlins can be integrated into existing building designs, thanks to their flexible installation options and the availability of processing services that allow them to be customized to fit a wide range of architectural styles and structural requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4