Introduction to Manual Corn Threshing Machines

Exploring the realm of agricultural efficiency, the manual corn threshing machine stands as a pivotal innovation. This category encompasses devices designed to separate kernels of corn from the cob, a process traditionally performed by hand. The significance of these machines lies in their ability to streamline the post-harvest process, catering to the needs of small to large-scale food processors.

Types and Applications

There exists a variety of manual corn threshers tailored to diverse operational scales. These machines are integral in the processing of grains and are adept at handling various foodstuffs with hulls. Their applications extend beyond corn to include legumes like soybeans, grains such as rice, and even nuts. The adaptability of these machines makes them indispensable in the agricultural sector.

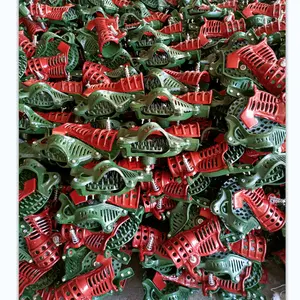

Features and Materials

The construction of a manual corn sheller typically involves durable materials capable of withstanding the rigors of grain processing. Stainless steel components are common, ensuring longevity and resistance to wear. The design of these machines prioritizes user safety and efficiency, with ergonomic features that facilitate ease of use and maintenance.

Advantages of Manual Threshing

Opting for a hand corn thresher brings forth several advantages. These machines are cost-effective, requiring no power source, thus reducing operational costs. They are also portable, allowing for flexibility in usage across different locations. The simplicity of the manual mechanism reduces the need for specialized training, making them accessible to a broader user base.

Efficiency and Productivity

Incorporating a corn kernel remover into food processing lines can significantly enhance productivity. By automating the labor-intensive process of shelling, these machines free up valuable time, allowing businesses to scale operations and increase output. The manual operation ensures that the process can continue in areas with limited access to power, ensuring continuous productivity.

Choosing the Right Machine

Selecting the appropriate corn dekerneling machine is crucial for meeting specific processing needs. Factors to consider include the volume of produce to be processed, the variety of crops, and the available space for the equipment. Alibaba.com offers a platform where buyers can compare different models, ensuring they find a machine that aligns with their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4