What is Advanced Mining Gear

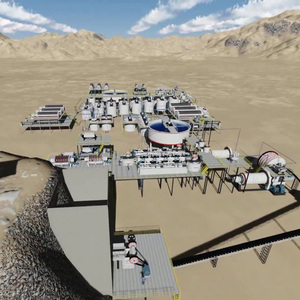

Advanced Mining Gear refers to the sophisticated tools, equipment, and technology used in modern mining operations. These tools are designed for various stages of the mining process, from exploration and extraction to processing and logistics. They are intended for use by mining companies, geologists, and engineers who require efficient and reliable gear to maximize the potential of a mining site. The principles on how this equipment works are based on a combination of mechanical, electrical, and sometimes hydraulic power to perform its functions.

For instance, advanced drilling equipment utilizes high-pressure air or water to cut through rock and soil, allowing for the installation of explosives for ore extraction. Other gear such as crushing and grinding mills enable the processing of large chunks of material into smaller, more manageable pieces. Additionally, there are advanced systems for conveying, sorting, and separating materials based on their physical properties.

These technologies have revolutionized the mining industry by significantly improving productivity, safety, and environmental impact. Companies that invest in such gear can operate more effectively in competitive markets and contribute to sustainable mining practices. Advanced Mining Gear is, therefore, an essential component for any mining operation that aims to stay ahead in the field of production.

Types of Advanced Mining Gear

Several types of advanced mining gear are available to address specific challenges in different mining scenarios:

-

Automated Conveyor Systems transport heavy materials such as ore over long distances without the need for manual intervention. These systems reduce the reliance on human labor and provide consistent material handling.

-

Drone-Based Surveys utilize unmanned aerial vehicles to capture detailed images and data for geological mapping, surveying, and planning. This technology is particularly useful for large-scale open-pit mines.

-

Virtual Reality Training Simulators offer a safe yet realistic environment for training operators on various mining equipment. This immersive experience can improve the learning curve for new employees and enhance the efficiency of training without risking equipment or the environment.

-

Robotic Systems are revolutionizing the mining industry with robots that can perform complex tasks autonomously. These systems are instrumental in areas where conditions are hazardous for humans but consistent performance is required.

-

High Precision GPS Systems have become standard in open-pit mining for their ability to provide accurate location data necessary for safety protocols and efficient extraction of resources.

How to choose Advanced Mining Gear

Selecting advanced mining gear involves careful consideration of several factors to ensure that the chosen equipment meets the specific needs of your business. Here are some key points for businesses to keep in mind:

-

Applicable Industry: Choose equipment designed for your industry. Whether it's for construction works, manufacturing plants, or mining operations will determine the type of gear needed.

-

Core Components: Inspect the core components such as motors, bearings, gears, engines, etc., to ensure durability and longevity in harsh conditions.

-

Local Service Location: Consider the location where you will be operating. Having access to service centers or support in your region can be crucial for maintaining equipment uptime.

-

Material and Technology: Choose materials that can withstand the specific conditions of your mine, like high-grade steel for strength or corrosion-resistant coatings for harsh environments.

-

After-Sales Service: Opt for suppliers who provide comprehensive after-sales services like maintenance support or online technical assistance to ensure continuous operation of your machinery.

By taking these factors into account when choosing advanced mining gear from Alibaba.com's extensive selection, businesses can make informed decisions that cater to their operational requirements.

About Advanced Mining Gear on Alibaba.com

Alibaba.com offers an expansive marketplace where businesses can discover a comprehensive selection of advanced mining gear suited for various applications across different industries. The platform's global reach connects buyers with reputable suppliers from around the world, providing access to cutting-edge technology and innovative solutions that meet rigorous industry standards. Whether you're outfitting an entire workforce or sourcing specialized equipment for unique mining tasks, Alibaba.com's extensive network ensures you find exactly what you need.

With over two decades of experience facilitating B2B transactions, Alibaba.com has established itself as an essential resource for companies seeking reliable suppliers and state-of-the-art products. The platform's commitment to streamlining international trade is evident through its user-friendly interface that supports multilingual communication and mobile-friendly buying options. Moreover, Alibaba.com's Trade Assurance service offers peace of mind by safeguarding payments until orders are fulfilled to satisfaction.

The platform's extensive assortment allows businesses to explore a multitude of advanced mining gear options without geographical constraints. From robust protective garments to cutting-edge communication devices, each product category is curated to ensure that businesses can source gear that not only meets their operational demands but also aligns with their budgetary considerations. By choosing Alibaba.com as your sourcing partner, you leverage a robust ecosystem designed to support businesses in achieving their operational objectives efficiently and effectively.

Common FAQs for Advanced Mining Gear

What are the key components of an Advanced Mining Gear?

The key components include the motor, gearbox, bearings, gear, and motor type. These parts are designed to ensure efficiency, durability, and power transmission in mining equipment.

How can I determine the right motor type for my mining equipment?

Consider the power requirements and operational needs of your equipment. AC motors are typically used for their efficiency in continuous operations, while DC motors may be used for their ability to handle variable speed and torque control.

What does the machinery test report mean for Advanced Mining Gear?

A machinery test report provides information about the equipment's performance and durability. It can include measurements such as load tests, material analyses, and assessments of operational safety.

Can I find Advanced Mining Gear for specific types of mining operations?

Yes, suppliers on Alibaba.com offer a variety of Advanced Mining Gear tailored to specific types of mining operations such as coal mining, gold mining, and construction works.

What should I consider regarding the material quality of the gear components?

Material quality is crucial for the gear components as they must withstand extreme operating conditions. High-quality materials like alloy steel or stainless steel are commonly used.

How does the local service location impact my purchasing decision?

The local service location can impact your purchasing decision if you require on-site support or installation services. Choosing a supplier with a nearby service location can provide quicker assistance when needed.

Is it possible to get customized Advanced Mining Gear based on my specific requirements?

Many suppliers offer customization options for their products, allowing you to specify certain features to meet your operational needs.

What after-sales services are typically provided with the purchase of Advanced Mining Gear?

After-sales services may include online support, video technical support, field maintenance and repair service, or access to engineers who can service machinery overseas.

How do I ensure that the Advanced Mining Gear is compatible with my existing equipment?

Check the product specifications and consult with the supplier regarding compatibility. It's also beneficial to compare the structural requirements and mounting configurations to ensure a proper fit.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4