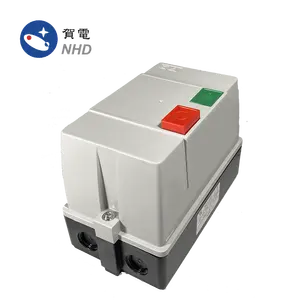

A motor starter is an essential device in the control of electric motors, designed to safely initiate and halt the operation of a motor. It serves to manage the electrical power that is supplied to a motor and protects against electrical overloads. Motor starters are widely used across various industries, including machinery repair shops, manufacturing plants, and construction sites, to ensure the efficient and safe functioning of motors.

Types and Characteristics of Motor Starters

The motor starter category encompasses a range of types, each with a unique structure to suit specific applications. Direct Online (DOL) starters are straightforward, providing full voltage to the motor at startup, ideal for small motors. Star-Delta starters are designed for larger motors, initiating at a lower voltage to reduce the starting current and then transitioning to the normal operating voltage. Magnetic starters, which can be full voltage or reduced voltage types, offer the advantage of remote operation and are suitable for multiple start-stop cycles. Soft starters and variable frequency drives (VFDs) are advanced types that gradually increase the voltage to the motor, thereby reducing mechanical and electrical stress. Understanding the characteristics of these various starters is crucial for selecting the right one for a specific motor application, ensuring both efficiency and longevity.

Structure and Operation of Motor Starters

The structure of a motor starter typically includes a contactor that switches the motor voltage, an overload relay that protects the motor from overcurrent, and often a control circuit that governs the starter's operation. In a DOL starter, the contactor directly connects the motor to the power supply, providing immediate full power. In contrast, a Star-Delta starter initially connects the motor windings in a star configuration to limit voltage and current, then switches to a delta arrangement for normal operation. Magnetic starters use an electromagnet to operate the contactor, which can be energized or de-energized to start or stop the motor. The physical components are designed to work in unison, providing a seamless start and stop mechanism for the motor, with the added benefit of overload protection to prevent damage to the motor from excessive current.

Materials and Properties

The materials used in motor starters are chosen for their electrical conductivity, durability, and resistance to environmental factors. Copper and aluminum are commonly used in the contacts and conductive pathways for their excellent conductivity and low resistance, which is crucial for efficient current flow. Steel and iron provide structural integrity to the frame and housing, while advanced plastics are used for insulation to prevent short circuits. These materials are selected not only for their functional properties but also for their longevity and ability to withstand the rigors of industrial environments. The choice of material affects the starter's performance, with certain metals like copper being preferred for their low resistance and high conductivity, which minimize energy losses and improve efficiency.

Business Usages and Industrial Applications

Motor starters are pivotal in a variety of business usages, from the heavy machinery in construction to the precision tools in manufacturing plants. In the automotive industry, they are used to control the paint shop conveyors, ensuring smooth operation. In food processing, they manage the motors in mixers and grinders, contributing to consistent product quality. In HVAC systems, motor starters regulate fans and compressors. These starters enable businesses to automate processes, increase productivity, and maintain safety standards, thereby creating significant business value and aiding in operational excellence. The versatility of motor starters allows them to be customized for specific applications, such as explosion-proof models for hazardous environments or corrosion-resistant versions for chemical processing plants.

Functions and Tasks

A motor starter is designed to perform several critical functions. It provides a controlled method of starting the motor, minimizing the impact of inrush current. It also allows for the stopping of motors, both in normal and emergency situations. Additionally, motor starters can reverse the motor's direction and protect it from electrical faults. These tasks are essential for the longevity and efficiency of motors in industrial settings. The starter's overload relay is particularly important, as it measures the motor's current and breaks the circuit if the current exceeds a preset level, thus preventing overheating and potential damage.

Features and Unique Selling Points

The distinct features of motor starters include their ability to integrate with modern control systems, offering features such as variable speed control and intelligent monitoring. Some starters come with diagnostic capabilities, allowing for preemptive maintenance alerts. These unique selling points set them apart from competitors by offering enhanced control, improved safety, and reduced downtime for businesses. The adaptability of motor starters to various industrial protocols and their compatibility with other control devices make them a central component in modern automation systems.

Benefits and Positive Outcomes

The use of motor starters brings numerous benefits to industrial operations. They protect expensive motor equipment from electrical damage, reduce the likelihood of unexpected downtime, and can improve energy efficiency. The positive outcomes of using a motor starter include a safer working environment, longer motor life, and potential cost savings on energy and maintenance. By ensuring a controlled start, motor starters also help in reducing mechanical stress on the motor and the driven equipment, leading to smoother operation and less wear and tear.

How to Use and Operate Motor Starters

Effective operation of a motor starter involves understanding the control interface, which may range from manual switches to sophisticated digital panels. Users should familiarize themselves with the starter's operation manual to ensure correct usage. For instance, setting the overload relay correctly is crucial to prevent false trips or motor damage. Regular testing of the starter's functionality, such as simulating overload conditions, can help ensure that the motor starter will perform as expected during actual operating conditions.

How to Choose the Right Motor Starter

Selecting the right motor starter requires an understanding of the motor's specifications, such as its voltage, current, and application. The environment in which the starter will operate is also a key consideration, as is the type of load the motor will drive. Consulting with a professional or using selection tools provided by manufacturers can aid in making the right choice. Factors such as the starting torque requirements, the frequency of start/stop cycles, and whether the application requires speed control should also be considered when choosing a motor starter.

How to Clean, Maintain, and Install Motor Starters

Cleaning and maintaining a motor starter involves regular inspections for signs of wear, ensuring that connections are tight and free of corrosion. Installation should adhere to electrical codes and standards, and it's often recommended to be performed by a certified electrician. Following the manufacturer's guidelines for cleaning, maintenance, and installation will ensure the starter's longevity and reliability. Preventative maintenance, such as periodically testing the operation of the overload relay and ensuring that the contactor contacts are clean and in good condition, is essential for reliable operation.

What are the considerations for international buyers?

International buyers on Alibaba.com should consider the motor starter's place of origin, as it may affect the availability of local service locations and the compatibility with regional electrical standards. Additionally, buyers should evaluate the machinery test report and the phase of the motor starter to ensure it meets their specific requirements. It's also important to consider the certifications and compliance with international standards, which can affect the ease of integration and legality of use in different countries.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4