Introduction to PET Bottle Capping Machines

The realm of packaging is revolutionized by the advent of PET bottle capping machines, a pivotal component in the automation of sealing bottles efficiently. These machines are designed to cater to a variety of capping needs, ensuring that plastic and glass bottles receive the perfect seal every time. The versatility of these machines allows them to be integrated into different production lines, serving industries ranging from beverages to pharmaceuticals.

Types and Applications

From manual PET bottle capping machines to fully automated systems, the range available caters to diverse production capacities and budgets. These machines are not just limited to sealing PET bottles but are also adept at handling various other types, including glass and metal containers. The plastic bottle packaging machine variants are specifically designed to manage the nuances of plastic containers, ensuring a tight seal that maintains product integrity.

Features and Materials

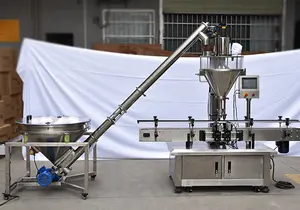

A PET bottle capping machine is typically constructed with a stainless steel body, providing durability and suitability for stringent hygiene standards required in food and pharmaceutical production. Advanced models come equipped with sensory probes and customizations such as different sensors and conveyor belts, enhancing the machine's capability to adapt to specific production needs. The plastic bottle cap sealing machine often includes adjustable settings for colors and sizes, allowing for a tailored approach to capping.

Advantages of Automation in Capping

Embracing the efficiency of a PET bottle sealing machine translates to a significant uptick in production speed and accuracy. The automation minimizes the need for extensive manual labor, allowing a single operator to manage the capping process. Energy-efficient mechanisms within these machines ensure that their operation does not lead to excessive electrical consumption. Moreover, the precision of an induction sealing machine for plastic bottles ensures that caps are sealed without damaging the bottle, preserving the product's quality.

Customization and Adaptability

Flexibility is a hallmark of the plastic bottle capper, with options for customization that can integrate seamlessly into existing production setups. Whether it's adjusting the machine to fit specific bottle sizes or incorporating unique cap designs, these machines are designed to be adaptable. The plastic bottle foil sealing machine is another example of how specific applications can be catered to, providing a hermetic seal for products that require an extra layer of protection.

Choosing the Right Machine

Selecting the appropriate PET bottle capping machine involves considering production capacity and specific operational needs. The Alibaba.com platform showcases a wide array of suppliers offering a variety of machines, including the pet bottle filling and capping machine, which combines two critical processes in one system. Prospective buyers can explore the options, compare features, and find a machine that aligns with their production requirements without the hassle of navigating through multiple vendors.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4