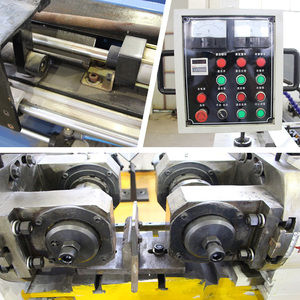

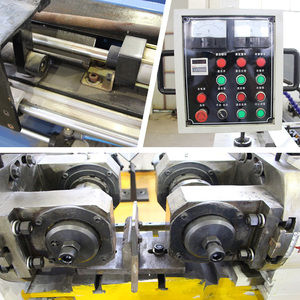

200 Model CNC Plastic PVC Pipe Threading Machine/pipe Thread Rolling Machines/pvc Pipe Making Machine Fully Automatic

Moto Automatic Cnc Steel Bar Rod Pipe Nipple Pipe Threading Knurling Machine / Rebar Thread Rolling Knurling Machine

A thread machine is also known as threading machine or pipe thread machine. It is utilized to form the threads found on pipes and other common materials used in building electronics, projects, and the fabrication of diverse sorts of merchandise. The thread winding machine makes machine thread processing during pipe installation simpler and quicker and diminishes labor intensity to some extent.

Ordinarily, thread machines can be divided into three types: mechanical thread machine, power-operated thread machine, and handheld thread machine. A mechanical thread machine uses a manually worked ratchet mechanism. This thread machine sort is appropriate for pipe materials that are soft and lightweight, regularly up to 2 inches (5.08 cm) in diameter. It is regularly utilized for small-scale objects or threading requirements that are not frequent or broad. Power-operated thread machine can also be called a motorized thread machine, which is equipped with an electric motor to rotate the die head automatically. Mainly, the thread winding machine can be powered by three kinds of power: electric power, battery, and hydraulic. The advantage of electric power is its solid and continuous supply runs the equipment proficiently and ceaselessly. However, using electric power needs to burn coals, so maybe it is not that eco-friendly. Batteries are also able to provide the thread machine with stable and clean power. They are portable, and there are diverse voltage, current, and power capabilities to choose from. Hydraulic is more durable and more economical, and it is eco-friendly as well. All these power sources can help reduce some physical efforts and handle some of the heavy-duty and high-volume repetitive work, making the machine a easy threader. A handheld thread machine could be a portable, electric-powered tool utilized for threading. It is regularly smaller and more lightweight, which is commonly utilized when transportability is fundamental or when threading requirements happen on-site or in tight spaces.

Firstly, decide the sort of pipe and guarantee the area encompassing it is clear of any dirt or loose particles. Secure, trim, and smoothen the pipe as preparation. Select the die size for the pipe diameter and threading standard, or read the instructions provided by the manufacturer to determine the option. Apply threading oil and place the pipes to start threading. Exert pressure to initiate the process through the pipe wall until the pipe is fully cut through by the thread machine. After threading, just reverse the rotation and seal the threaded connections properly to prevent leaks and protect the pipes from corrosion.