Introduction to Plastic Ball Machines

The realm of manufacturing is diverse, with specialized machinery tailored for specific products. Among these, the plastic ball machine stands out as a category dedicated to the production of plastic balls used in various applications. This machinery encompasses a range of processes and technologies designed to meet the demands of plastic ball manufacturing.

Understanding the Molding Processes

The creation of plastic balls involves several molding techniques. Injection Blow Molding utilizes a core rod that remains integral throughout the process. Extrusion Blow Molding and Injection Stretch Blow Molding are other prevalent methods, each with its unique approach to shaping plastic materials into durable balls. These processes are critical in the production of everything from simple play balls to intricate valve components in the PVC ball valve making machine.

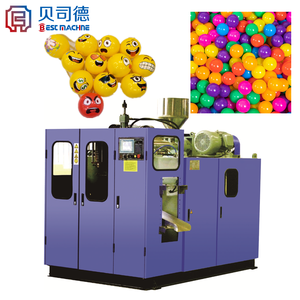

Features of Plastic Ball Manufacturing Machines

When exploring the capabilities of a plastic ball manufacturing machine, it's essential to consider the features that enhance its efficiency and output quality. Equipment may offer full proportional control over various components, ensuring precision in production. Features like adjusted angled blow pins and advanced control systems exemplify the technological sophistication of these machines. Specific models are equipped with integrated systems for handling scrap, discharging finished products, and facilitating the loading process, streamlining the entire manufacturing cycle.

Materials and Sustainability

Material selection is a pivotal aspect of plastic ball production. Suppliers on Alibaba.com can recommend compounds that align with specific requirements, whether for durability, flexibility, or other properties. Additionally, the option for using recycled materials is available, reflecting a commitment to sustainability in the industry. For products necessitating specialized material analysis, services for plastic testing and laboratory analysis are accessible to ensure compliance with stringent standards.

Choosing the Right Machine for Your Needs

Selecting the appropriate plastic ball making machine hinges on understanding the specifications and operational needs of a business. The platform connects buyers with a variety of machines, each varying in specifications to cater to different scales of production and types of plastic balls, from simple toy balls crafted by a PVC toy ball making machine to more complex applications. It's crucial to assess the different blow molding processes to identify the machine that aligns with your production goals.

Connect with Suppliers

For businesses in pursuit of detailed information and specifications, Alibaba.com serves as a conduit to a network of experienced suppliers. These professionals can provide insights into the nuances of blow molding technology and assist in selecting the right plastic ball banane ki machine without the constraints of brand affiliations. Engaging with suppliers through the platform facilitates informed decision-making tailored to the unique requirements of your manufacturing processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4