Introduction

Plastic shields, once seen merely as protective barriers, have evolved into innovative tools that shape our everyday lives. From the pioneering work of manufacturers in the 1970s to the present day, these shields have undergone a remarkable transformation. Today, they are not just about protection but also about innovation, creativity, and self-expression. They have found diverse applications across various industries, including healthcare, automotive, consumer electronics, and food and beverage. This article delves into the evolution, innovative uses, and future trends of plastic shields, highlighting their surprising roles in our daily lives.

The Evolution of Plastic Shields

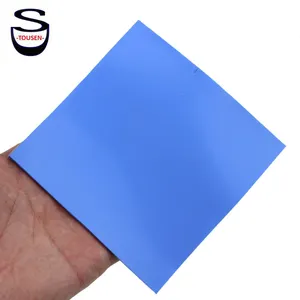

The evolution of plastic shields is deeply rooted in the history of the polycarbonate thermoforming industry. Established in the mid-1970s, the industry initially focused on creating acrylic fairings for motorcycles. However, recognizing the potential of polycarbonate, a robust optical plastic, they expanded their product line to include optically correct polycarbonate shields. Despite the challenges of working with polycarbonate, the industry introduced a line of high-strength, clear shields with superior abrasion and chemical resistance. This innovative step forever changed the field of plastic shields.

From Protection to Innovation: A Paradigm Shift

As the world navigates the 'new normal,' face masks and face shields have become integral to our daily lives. They have evolved from being a piece of personal protective equipment to a unique canvas for self-expression and creativity. From innovative materials to eye-catching patterns, these masks and shields prove that staying safe doesn't have to be boring. For instance, some face shields are created from plastic using the power of origami, while others are designed to look like you aren't wearing one. This paradigm shift from protection to innovation is transforming the way we perceive and use plastic shields.

Innovative Uses of Plastic Shields in Various Industries

Plastic shields have found innovative uses in the face mask industry, enhancing safety and functionality. For instance, 'Ear Guards' for medical face masks have been invented using 3D printing technology. Similarly, a unique origami design for a face shield, called the 'HappyShield', can be folded out of a single plastic sheet. In another instance, a concept for a reusable plastic face shield has been released. These examples highlight the versatility and adaptability of plastic shields in various applications, primarily in enhancing personal protective equipment.

Healthcare and Medicine

In the realm of healthcare and medicine, plastic shields have become an essential tool for personal safety. Specifically, single-use face shields, made from anti-fog P.E.T. plastic, have proven vital in protecting individuals from viral contamination, such as COVID-19. These shields, often paired with face masks, are a significant addition to infection control procedures. The comfort of these shields is ensured by a polyurethane foam strip and a non-latex elastic headband. Some models even offer self-assembly and adjustable headbands for enhanced comfort.

Automotive and Transportation

In the automotive and transportation industry, plastic shields, in the form of high-performance plastics, are shaping the future of transportation. Polypropylene, a thermoplastic polymer, is frequently used due to its excellent chemical and heat resistance. It's found in car bumpers and gas cans. Polyvinyl Chloride (PVC) is a flame retardant plastic used for dashboards and body parts. Polycarbonate, resistant to impact and weathering, is used for car bumpers and headlight lenses. Acrylonitrile Butadiene Styrene (ABS) is used for steering wheel covers, dashboards, and body parts, absorbing and redistributing energy during an impact.

Consumer Electronics

In the realm of consumer electronics, plastic shields, specifically plastic enclosures with RFI/EMI shielding, play a crucial role. These shields prevent frequency disturbances that could damage electronic devices. RFI and EMI can cause significant interference in devices, affecting their normal operations. Therefore, the use of plastic shields ensures the successful operation of many electronic devices, making them an indispensable component in the consumer electronics industry.

Food and Beverage

In the food and beverage industry, various types of plastics play a crucial role in packaging. PET plastics, known for their strength and lightweight build, are commonly used in sauce bottles and soft drink containers. HDPE plastics, versatile and durable, are found in milk cartons and water bottles. PVC plastics, with their excellent dimensional stability, are used in food foils and cling wraps. LDPE plastics are used in bread and frozen food packaging, while PP plastics are found in microwaveable containers and chip bags. PS plastics are used extensively in food packaging and containers. Other innovative plastics like PLA, derived from renewable sources, are used in eco-friendly products.

Environmental Impact and Sustainability

In the realm of sustainability, innovative initiatives are making strides by incorporating recycled material into over 1 million PPE face shields. This innovative approach not only safeguards workers and customers but also protects our oceans by preventing plastic waste from reaching them. This sustainable alternative adheres to the highest quality and safety standards, demonstrating that environmental responsibility and practical utility can go hand in hand. This effort is particularly significant in industries like food and beverage, supporting their reopening and thriving in the new normal.

The Future of Plastic Shields: Trends and Predictions

In the future, smart technology like AI could improve face visors. These high-tech shields could warn you about dangers before they happen. Also, they could learn from past data to give you safety tips that are perfect for the kind of work you're doing in the lab. Given the increasing focus on sustainability, some manufacturers are developing solar-powered face masks. These can harness natural light to power small fans, maintaining airflow and reducing fogging. This is particularly useful in labs that handle volatile chemicals requiring superior ventilation.

Conclusion

The journey of plastic shields from simple protective barriers to innovative tools is a testament to human ingenuity. They have transformed from being products of necessity to canvases of creativity, finding applications in various industries. Whether it's enhancing safety in healthcare, shaping the future of transportation, ensuring the smooth operation of electronic devices, or contributing to sustainable packaging in the food industry, plastic shields have proven their versatility. As we look to the future, the integration of smart technology and sustainability considerations promises to further revolutionize the role of plastic shields in our lives. Thus, the story of plastic shields is far from over; it's just beginning.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4