Rice Planting Machine: An Overview

The rice planting machine stands as a cornerstone in modern agricultural equipment, designed to streamline the process of sowing rice seeds. These machines vary in complexity and size, catering to different scales of rice cultivation. From small-scale operations to expansive industrial farms, the utility of a rice planter is undeniable in enhancing planting efficiency.

Types and Applications

Different types of rice planters, such as the paddy transplanter and the rice transplanting machine, serve specific purposes. The paddy transplanter is particularly adept at transferring pre-germinated seedlings into paddy fields, while manual rice planters offer a cost-effective solution for smaller or more traditional operations. The choice of machine depends on the scale of the operation and the specific needs of the rice cultivation process.

Features and Operating Styles

Rice planting machines come with a variety of features designed to suit diverse farming needs. Multi-row planters with capacities ranging from two to eight rows allow for customization based on the size of the operation. Additionally, the operational style of these machines varies, with options including walk-behind and ride-on models. The walk-behind rice plantation machine is a staple for operations with a larger workforce, while the ride-on models prioritize labor conservation, offering different comfort levels with seating or standing platforms.

Power and Efficiency

The efficiency of a rice growing machine is often dictated by its power source. Diesel and electric-powered models provide rapid operation with minimal manual input, focusing primarily on navigation. In contrast, manual paddy transplanters, which are hand-operated, present an economical entry point into mechanized rice planting, requiring physical input from the operator. Pedal-operated machines strike a balance, offering a compromise between manual effort and operational cost.

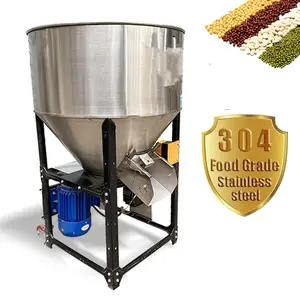

Materials and Advantages

Constructed from durable materials designed to withstand the rigors of farming, rice planting equipment is built for longevity. The advantages of integrating a paddy planting machine into agricultural practices include increased efficiency, uniformity in planting, and a potential increase in yield. These machines also contribute to the reduction of labor intensity and the optimization of planting seasons.

Choosing the Right Machine

Selecting the appropriate rice sowing machine involves considering the specific requirements of the farm, such as the size of the area to be planted and the desired efficiency. With a range of machines available, from the robust kubota rice planting machine to simpler manual options, farmers can find the equipment that best aligns with their operational style and objectives.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4