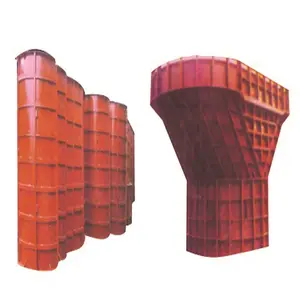

Round concrete forms play a pivotal role in the construction industry, greatly offering a versatile and reliable solution for creating various structures. The functionality of these round concrete forms extends beyond their basic purpose, making them indispensable in diverse applications. At the core of round concrete forms is their fundamental function – facilitating the creation of cylindrical structures. These forms are meticulously designed to ensure precision and consistency in shape, making them ideal for constructing columns, pillars, and other cylindrical elements in buildings and infrastructure projects. The inherent stability of 24-inch round concrete forms allows for efficient concrete pouring, resulting in structures with enhanced strength and durability.

Applications of round concrete forms

The versatility of 36-inch round concrete forms is exemplified by their extensive range of applications across various construction projects. From residential buildings to commercial complexes, these forms find utility in creating pillars that provide structural support. Additionally, they are instrumental in constructing bridges, tunnels, and other infrastructural components where cylindrical elements are integral to the design. The adaptability of round concrete forms ensures their relevance in diverse usage scenarios, contributing to the efficiency and durability of the structures they help create.

How to maintain round concrete forms

Ensuring the longevity and performance of round concrete forms for sale requires proper maintenance practices. Regular inspection for many signs of wear and tear, cleaning after each use, and adequate storage in a controlled environment are essential measures. Inspection should focus on identifying any damage and ensuring that the forms maintain their structural integrity. Proper maintenance not only extends the life of the forms but also contributes to the quality of the concrete structures they help produce. The utilization of round concrete forms involves a systematic process to guarantee optimal results. Proper alignment and securing of the forms before concrete pouring are crucial steps. The seamless assembly of the concrete forms ensures a smooth surface finish on the cylindrical structures. Moreover, understanding the concrete mix requirements and adhering to recommended pouring techniques enhances the overall effectiveness of the forms in the construction process.

Factors to consider round concrete forms

The material composition of 24 round concrete forms plays a pivotal role in determining the durability. B2B buyers must consider the type of material used, ensuring it meets industry standards for strength and resilience. This factor directly influences the longevity of the forms and the quality of the structures they help create. Different construction projects demand varying specifications for cylindrical elements. B2B clients should prioritize suppliers that offer customization options for round concrete forms. This includes considerations for diameter, height, and additional features that may be required for specific applications. Customization ensures that the forms align precisely with project requirements, contributing to efficient construction processes. Timely delivery of concrete forms for sale is critical in meeting project timelines. B2B purchasers should assess the supplier's logistics capabilities, ensuring they can fulfill orders promptly and reliably. Delays in delivery not only impact project schedules but may also incur additional costs. Evaluating the supplier's track record in logistics and delivery is essential for a seamless construction process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4