Discover the transformative capabilities of Sandblast Sand and take the surface treatment projects to new heights. Explore the various benefits of different types of sandblasting tools and choose the equipment that meets the personal needs. Whether tackling large-scale industrial tasks or small sandblaster focusing on intricate details, investing in high-quality sandblast sand products is essential. For a comprehensive selection of sandblasting equipment, visit Alibaba.com. Here, buyers can find various options to achieve professional results and enhance the efficiency of specific work.

Benefits of Sandblast Sand Products

The use of sandblasting cabinets, in particular, provides artisans and professionals with an enclosed space that is designed to contain the abrasive materials used during the sandblasting process. This containment is essential for reducing mess and ensuring that small particles are not inhaled, which is critical for safety. Furthermore, these cabinets are instrumental in achieving high precision on intricate tasks, including the delicate restoration of vintage items or the fine crafting of detailed components. For those working on smaller projects, compact sandblasters and mini sandblasters are a better idea. These scaled-down versions extend the convenience of sandblasting to those dealing with limited space or requiring a portable solution. The smaller units are easy to maneuver and facilitate precision work on smaller items.

Different Types of Sandblast Sand Tools

For those seeking to refine various surfaces, Alibaba.com offers an expansive selection of sandblasting tools tailored to specific needs. The conventional pressure blaster is a staple in the industry. It is known for its potent media stream, suitable for stripping coatings and quickly cleaning large surfaces. Siphon sandblasters are another popular choice, which recycles the blasting media, offering a cost-effective solution for continuous use. With their simple design, the gravity-fed sandblasters are suitable for occasional users who require an easy setup and operation tool. For precision tasks, such as engraving and detailed metalwork, the mini sand blaster is a go-to due to its fine control and ability to focus on tiny areas without affecting the surrounding material. Portable sandblasters offer flexibility and mobility, enabling the operator to move freely around large objects or take the tool to different job sites. Each type of sandblasting tool is engineered with specific applications, ensuring that clients can select a model that aligns with their project's scope and complexity.

Maintain the Sandblast Sand Equipment

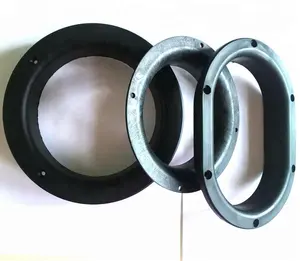

Maintenance of sandblasting pot is crucial for optimal performance and longevity. When operating the machine, it is important to regularly check for any signs of wear or damage, particularly in the hoses, nozzles, and seals, as these are high-wear areas. Ensuring that the abrasive media is clean and dry before use can prevent clogging and maintain the efficiency of the blasting process. Proper filtration and moisture separators should keep the air supply clean and dry, preventing internal corrosion and potential equipment failure. After each use, it is advisable to thoroughly clean the machine, removing any residual media or debris contributing to deterioration over time. Keeping a detailed log of maintenance activities can help track the equipment's condition and ensure it is always ready for the next project. By being diligent with these practices, operators can extend the life span of their sandblasting tools.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4