Understanding Sandblasting and Its Applications

Sandblasting, also known as abrasive blasting, is a process that involves propelling a stream of abrasive material against a surface under high pressure to smooth, roughen, or clean its surface. This technique is widely utilized across various industries for different purposes, from removing rust and paint to preparing surfaces for coating.

Types of Sandblasting Equipment

The equipment used for sandblasting varies, ranging from portable sandblasters that are convenient for small-scale projects to large, industrial machines. Portable abrasive blasters are particularly favored for their mobility, allowing operators to use them in various locations, including sandblasting near me services. For heavy-duty tasks, stationary models like the harbor freight abrasive blaster are commonly used due to their robust capabilities.

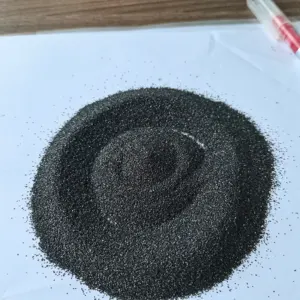

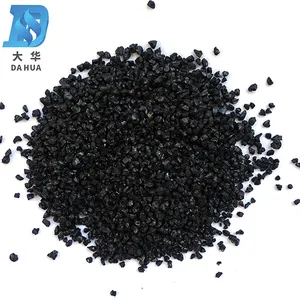

Choosing the Right Sand Blasting Sand

Selecting the appropriate sand blasting medium is crucial for effective sandblasting. Materials range from traditional sand to more specialized abrasives like steel grit, depending on the application's requirements. It's essential to choose the right medium to ensure the surface is treated correctly without causing unnecessary damage.

Innovations in Sandblasting Technology

Technological advancements have led to the development of various sandblasting methods. Dry ice abrasive blasting is a modern technique that uses dry ice pellets, providing a clean process that leaves no secondary waste. Similarly, wet sand blaster systems combine water and abrasive, reducing dust and making the process more environmentally friendly.

Enhancing Efficiency with Specialized Attachments

For specific tasks, attachments like the pressure washer sandblaster can be incredibly efficient. This tool connects to a pressure washer, combining water and abrasive for a powerful cleaning effect. Similarly, portable bead blasters are used for delicate surfaces where traditional sandblasting could be too harsh.

Safety and Environmental Considerations

While sandblasting is effective, it is also essential to consider safety and environmental impacts. Operators should always use appropriate protective gear, and when possible, opt for services like dustless blasting near me that minimize airborne particles, offering a safer and cleaner alternative to traditional sandblasting methods.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4