Good Quality 80t 100 Tons 160tons Cnc Press Brake And Bending Machine For Sheet Metal Processing Hydraulic Plate Bender

2023 Hot Sale 50T2500 E22 Sheet Metal Bending Machine Hydraulic Press Brake

Cheap CNC Press Brake Hydraulic Mini Sheet Metal Bending Machine 40T1600 Small Miniature Folder Machine

BEKE Hydraulic Bending Machine CNC Press Brake WC67K 63T3200 Sheet Metal Bending Machines

Upscale Excellent Cnc Hydraulic Metal Shearing Machine For Repair Factory

New style cnc press brake and bending machine for sheet metal processing

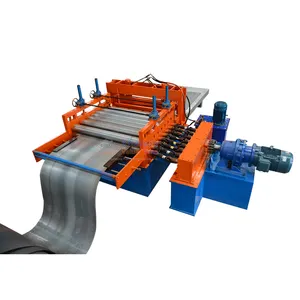

Hot Width 1300 mm Automatic Metal Steel Coil Slitting And Winding Machine Production Line For Metal Processing Plant

DXTECH 80T/2000mm CNC Press Brake hydraulic metal sheet plate iron bending machine

Machine for cutting and bending sheet, sheet press brake with European CE Standards from HARSLE

Rbqlty Cnc 4 Axis Cnc Steel Bending Machine Metal Sheet Folding Bending Hydraulic CNC Press Brake

Roof Sheet Metal Light Gauge Cutting And Form Machine, Cutting To Length Roll Form Machine

HARSLE Electrohydraulic Bending Machine Cnc Press Brake Machine For Sale

Wide Working Table Press Brake 200t/5000mm Steel Bending Machine For Precision Instruments

BL GKS-16030 160T 200T 3000MM 4+1 axis stainless steel fabrication metal sheet CNC press brake

Fully Automatic 100t/4000mm Sheet Metal Bending Press Brake Machine For Metalworking

3M leading cnc metal folding machine/ Metal Plate Hydraulic Sheet Metal Press Brake

2023 hot sale automatic bending machine price press brake cnc bending machine bending irons sheet metal cutting and bending mach

User Friendly Machine Full Electric Bending Mini Press

Good price WC67Y 125 ton 3200mm Press Brake Stainless Steel Bender Hydraulic CNC Sheet Metal Bending machine 160*3200

Hot sale CNC Bending machines Hydraulic Sheet Metal 80 100 125 Ton sheet metal folding press brake machine

CNC Press Brake Machine For Metal Sheet

ADV 508 Siemens motor high configuration sheet metal sander deburring machine for Edge Rounding And Laser Oxide Removal

Machine Plate Bender for Sheet Metal Working Metform Manual Sheet Bending Folding Provided 80 Manual Press Brake Machine 150 540

Cnc Sheet Metal Bending Machine Steel Bending Machine WC67K 125T/3200 6+1 Axis Hydraulic Press Brake Stainless Plate Bending 120

Hydraulischen Abkantpresse 80T 400T CNC Sheet Metal Bending Machine Pressbrake Press Brake

Three Layer Metal Corrugated Iron IBR Trapezoidal Roofing Panel Roof Sheet Tile Making Machinery Cold Roll Forming Machine

European Standard Sheet Metal CNC Press Brake Hydraulic Bending Machine Manufacturer

Corrugated Sheets Roofing Machine Tile Making Machine Corrugated Roofing Tile Roll Forming Machine

4ft 8ft 10ft Small iron plate hand folder sheet metal bending machine

Manufacturing Metal Roofing Sheet Tile Press Making Roll Forming Machine

WC67K 125T/3200 4 Axis Hydraulic CNC Press Brake for Metal Steel Bending Machine

automatic copper hand operated bending machine cnc sheet bending machines prices laser cutting machine

High efficient WC67Y/K 40T 1600mm Mini type carbon steel Cnc hydraulic plate bending machine small hydraulic press brake

Fully Automatic Color Cold Press Corrugated Metal Roofing Panel Roll Forming Machine

High Quality Small Sheet Metal Hydraulic CNC/NC Press Brake Machine

ACCURL Hot Sales Panel Bender 2500mm Press Brake Bending Center folding machine smart china factory price

LIMING Factory Sale Automatic Cut To Length Line Machine metal sheet cutting machine cut to length line machine

Automatic Color Steel 490 Self Lock Standing Seam Roof Sheet Panel Cold Roll Forming Machine

Good quality factory directly trapezoidal Steel roof panel Sheet roll forming machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4