Introduction to Silicone Moulding Machines

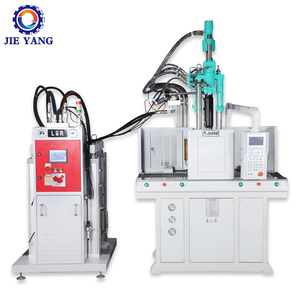

Silicone moulding machines are pivotal in the manufacturing sector, serving as the backbone for producing a myriad of silicone products. These machines are designed to shape silicone material into a vast array of items through a process known as injection moulding. This technique is widely utilized due to its efficiency in mass production and its ability to create intricate designs with precision.

Types and Applications

The versatility of silicone injection moulding equipment is evident in its various types, each tailored to meet specific production needs. From creating simple household items to complex medical components, these machines are integral in numerous industries. The application of silicone rubber moulding machinery extends to the automotive sector, consumer goods, and even high-stakes fields like aerospace and healthcare.

Technical Features and Materials

A silicone moulding machine is a marvel of engineering, incorporating specialized components to handle the silicone moulding process. The materials used in the construction of these machines, such as the steel bush in the clamping unit, are chosen for their durability and resistance to wear. The intricate design of the screw and clamping unit within the silicone plastic moulding machine ensures efficient material flow and precise force application, which are crucial for the moulding process.

Advantages of Silicone Moulding Machines

Investing in a silicone mould maker machine brings several advantages to the production line. These machines are known for their ability to produce components with improved accuracy, which is essential for applications requiring tight tolerances. Additionally, the advanced construction of these machines minimizes the need for frequent maintenance, such as lubrication, thereby reducing operational costs.

Choosing the Right Machine

Selecting the appropriate silicone moulding machine is crucial for your manufacturing process. Factors such as clamping force, which ranges significantly across different models, and the plasticizing capacity should be considered to match the specific requirements of your production. The design of the machine should align with the precise needs of your product, ensuring that you invest in the capacity and capabilities that your manufacturing process truly requires.

Conclusion

The silicone moulding machine is a key investment for businesses looking to streamline their production of silicone products. With a range of types and capabilities, these machines are engineered to meet the diverse needs of various industries. By carefully selecting the right machine, manufacturers can achieve efficiency, precision, and cost-effectiveness in their production processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4