Understanding SMT Stencil Wiper Rolls

Surface Mount Technology (SMT) stencil wiper rolls are essential components in the PCB assembly process. These specialized rolls are designed to clean stencils that apply solder paste to circuit boards, ensuring precision and preventing defects during the printing stage. The effectiveness of SMT stencil cleaning rolls is critical for maintaining the integrity of the soldering process, directly impacting the quality of the final electronic product.

Types and Materials of SMT Stencil Wiper Rolls

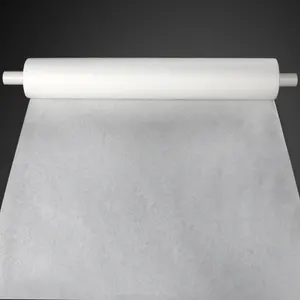

The variety of SMT stencil wiper rolls available on the market is extensive, catering to different machinery and applications. Common materials include non-woven fabrics, which are prized for their softness and absorbency, and polyester cellulose blends that offer a balance of strength and low lint properties. Each material is selected to provide the best cleaning efficiency for stencils without leaving residues that could compromise the soldering process.

Applications and Features

SMT stencil wiper rolls are utilized across various sectors in the electronics industry. Their primary application is in the cleaning of stencils within SMT machines, which is a pivotal step in ensuring the accuracy of PCB assembly. Features of these rolls include high tensile strength, excellent absorption, and compatibility with most cleaning solvents. This makes them versatile for use in different SMT printing systems and environments.

Advantages of Quality SMT Stencil Wiper Rolls

Utilizing premium SMT stencil wiper rolls in the assembly process offers numerous advantages. They reduce the frequency of stencil cleaning required, thereby increasing production efficiency. Additionally, the proper use of these rolls minimizes the risk of smudging and bridging defects in solder paste application, leading to a higher yield of PCBs that meet stringent quality standards.

Selection Criteria for SMT Stencil Wiper Rolls

When selecting SMT stencil wiper rolls, it is crucial to consider the roll's compatibility with the specific SMT printer and the type of solder paste used. The dimensions, core size, and material of the wiper roll must be appropriate for the equipment to ensure seamless integration and optimal cleaning performance.

Environmental Considerations

In line with environmental concerns, many manufacturers are now offering eco-friendly SMT stencil wiper rolls that are biodegradable or made from recycled materials. These options provide an opportunity for businesses to reduce their ecological footprint while maintaining high standards in their manufacturing processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4