Introduction to Sumitomo Inserts

Sumitomo inserts are integral components in the machining and metalworking industry, designed for precision and durability. These inserts come in various forms, including sumitomo electric inserts, sumitomo carbide inserts, and sumitomo ceramic inserts, each tailored for specific applications. They are crafted to meet the demands of modern manufacturing, offering solutions for turning, milling, and grooving operations.

Types and Applications

The range of Sumitomo inserts includes sumitomo turning inserts and sumitomo milling inserts, which are used in lathes and milling machines respectively. Sumitomo grooving inserts are specialized for precision grooving operations. These variations are engineered to enhance the efficiency of metal removal and to provide a superior surface finish on the workpiece.

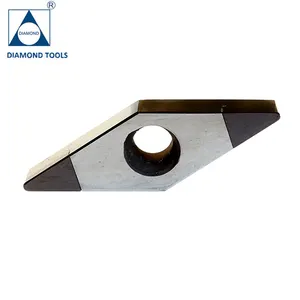

Features and Materials

Sumitomo inserts are made from robust materials such as carbide, CBN (cubic boron nitride), and PCD (polycrystalline diamond). Sumitomo carbide inserts are known for their resistance to wear and thermal deformation, making them suitable for high-speed applications. Sumitomo cbn inserts are ideal for hard material machining, while sumitomo pcd inserts are used for high-precision cutting of aluminum and other non-ferrous materials.

Advantages of Sumitomo Inserts

The advantages of using Sumitomo inserts in machining processes are manifold. They offer enhanced tool life due to the use of high-quality materials like sumitomo ac8025p and sumitomo acp200 grades, which are designed to withstand challenging conditions. The precision engineering of these inserts leads to improved accuracy and consistency in machining tasks, thereby reducing waste and increasing productivity.

Selection Considerations

When selecting the appropriate Sumitomo insert for a task, factors such as material compatibility, insert geometry, and the specific requirements of the machining process should be considered. It is crucial to choose an insert that matches the hardness and toughness of the workpiece material to optimize performance and extend tool life.

Conclusion

In conclusion, Sumitomo inserts are essential for businesses seeking reliable and efficient machining components. Alibaba.com offers a diverse array of these inserts to cater to various industrial needs. While exploring the extensive selection, buyers can find the right insert for their specific applications without the concern of quality compromises or exaggerated claims.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4