Understanding TPR and TPE: The Versatile Materials

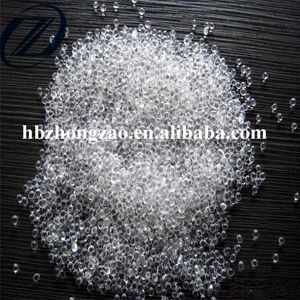

Thermoplastic Rubber (TPR) and Thermoplastic Elastomer (TPE) are innovative, flexible materials that are prevalent in various industries due to their unmatched properties. These materials combine the characteristics of rubber with the easy processing and recyclability of plastics, making them ideal for a wide range of applications.

Both TPR and TPE belong to a family of materials known as thermoplastics, which can easily be molded and remolded without losing their structural integrity. Their unique blend of flexibility, durability, and ease of processing grants manufacturers the ability to create products tailored to specific needs.

Types of TPR and TPE: Exploring the Variants

- TPR Types:

- Polyolefin TPR: Offers excellent weather resistance and is commonly used in outdoor applications.

- Synthetic Rubber TPR: Provides better elasticity and is often used in footwear and automotive components.

- TPE Types:

- SBS (Styrene-Butadiene-Styrene): Known for superior bonding properties, ideal for adhesives and sealants.

- SEBS (Styrene-Ethylene-Butylene-Styrene): Offers excellent UV resistance and is used in consumer goods and medical applications.

Applications of TPR and TPE: Where These Materials Shine

- Consumer Products:

- Used in the manufacture of grips for tools, household items, and sporting goods due to their comfortable texture.

- Widely used in the production of soft-touch elements for electronics and beauty products.

- Automotive Industry:

- Commonly utilized for seals, gaskets, and other component parts that require flexibility and durability.

- Enhances aesthetic appeal in vehicle interiors by providing soft-touch surfaces.

- Medical Applications:

- Perfect for manufacturing medical devices that require flexibility and sterility.

- Used for soft tubing and seals where a rubber-like quality is essential.

Advantages of TPR and TPE: Why Choose These Materials?

- Durability: Both TPR and TPE are resistant to wear and tear, making them long-lasting options for various applications.

- Flexibility: Their elastic properties allow for easy manipulation without breaking, ideal for products requiring movement.

- Environmental Benefits: Both materials are recyclable, contributing to more sustainable manufacturing practices.

- Low Maintenance: These materials are easy to clean and maintain, making them suitable for consumer goods and medical applications alike.

- Customizability: TPR and TPE can be easily colored and fashioned into diverse shapes, enabling manufacturers to innovate product designs effectively.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4