Free Sample High Quality Heavy Duty Defensive Barriers Defensive Bag Gabion Bastions/Welded Mesh Barrier Bastion

3mm Spring Coated Steel Gold Wire Mesh Sheets 20x20x1.5mm Fence Decorative Diamond Brass Wire 18 Mesh

Wire mesh sheet plastic is a versatile material with a broad spectrum of applications across various industries. This type of mesh combines the durability of steel with the flexibility and corrosion resistance of plastic, making it an ideal choice for a multitude of uses.

From pvc coated mesh panels to lightweight yet sturdy partitions, wire mesh sheet plastic is an adaptable product. It serves as a critical component in creating barriers for animal enclosures, providing a secure environment that balances visibility with protection. In the industrial sector, this mesh is integral to filtration systems, aiding in the separation and purification processes. Its application extends to the construction realm, where it contributes to the reinforcement of concrete, offering an alternative to traditional rebar.

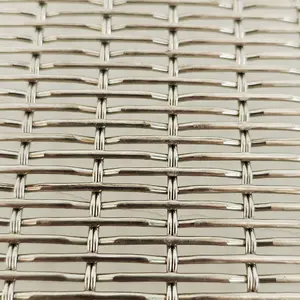

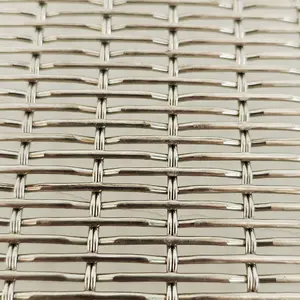

The construction of wire mesh sheet plastic typically involves a steel core that is thoroughly coated with a layer of plastic, often PVC. This coating not only enhances the mesh's resistance to environmental factors but also adds to its aesthetic appeal, allowing for use in visible areas without compromising on looks. The mesh is available in various weaves, including tight configurations for fine filtration and loose weaves for larger barriers.

One of the primary advantages of wire mesh sheet plastic is its resilience. The combination of steel and plastic ensures a long-lasting product that withstands harsh conditions without succumbing to rust or corrosion. Additionally, the flexibility of the mesh makes it easy to customize and shape for specific projects, from agricultural fencing to security applications.

Customization is a key feature of wire mesh sheet plastic, with options ranging from hexagonal mesh patterns to diamond designs. This adaptability allows for a tailored approach to each project, ensuring that the mesh meets the exact requirements of the task at hand. Whether it's for creating intricate designs or fulfilling functional needs like air purification or light diffusion, the mesh's versatility is unmatched.

Selecting the appropriate wire mesh sheet plastic for a project is crucial. Factors to consider include the size of the mesh openings, the type of plastic coating, and the overall dimensions of the sheets. It's important to assess the specific needs of the application to determine the most suitable mesh type. For those seeking to employ this material in their projects, a comprehensive range of options is available to explore and compare.