Introduction to Wood Board Making Machines

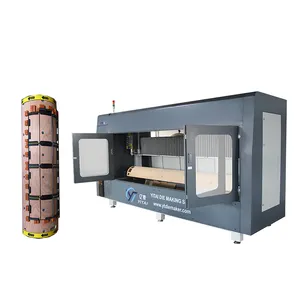

The realm of woodworking is vast and complex, with the wood board making machine standing as a cornerstone for professionals in the industry. These machines are pivotal in the production of various wood-based panels, serving as the backbone for both small-scale artisans and large-scale industrial operations. The category encompasses a range of machinery designed for the creation of diverse wood products, from sturdy MDF panels to lightweight particle boards.

Types of Wood Board Making Machinery

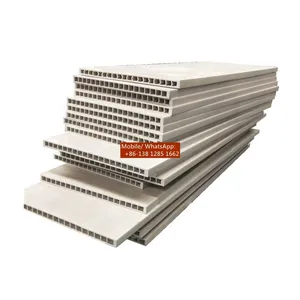

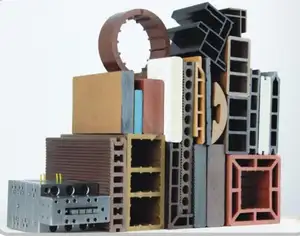

Within this category, several types of machinery cater to different production needs. The mdf board making machine is tailored for medium-density fiberboard production, a material known for its versatility in furniture and construction applications. In contrast, the particle board making machine and particle board manufacturing machine focus on producing boards from wood chips and sawdust, offering a cost-effective solution for various applications. Additionally, the sawdust board making machine is specialized for creating boards from finer wood waste, optimizing material usage and sustainability.

Applications and Features

Wood board making machines are integral in manufacturing panels for furniture, cabinetry, and construction. These machines boast features that enhance production efficiency, such as advanced control systems and precision cutting tools. The particle board furniture making machine specifically caters to the furniture industry, engineered to produce boards that are easy to shape and finish. The versatility of these machines allows for a wide range of applications, ensuring they meet the demands of various woodworking projects.

Materials and Advantages

The construction of wood board making machines involves robust materials that withstand the rigors of heavy usage. The advantages of using these machines are manifold, including improved production speed, consistent product quality, and the ability to recycle wood waste into valuable products. By utilizing wood residues, machines like the sawdust board making machine contribute to a more sustainable manufacturing process, reducing waste and optimizing resource use.

Choosing the Right Machine

Selecting the appropriate wood board making machine requires careful consideration of the intended output and operational scale. Prospective buyers should assess the specifications of each machine, ensuring it aligns with their production goals and material preferences. It is crucial to consider the machine's compatibility with the type of wood product being manufactured, whether it's for creating dense MDF boards or lightweight particle boards.

Conclusion

The investment in a suitable wood board making machine can significantly impact the efficiency and quality of wood product manufacturing. While exploring options on Alibaba.com, buyers have access to a comprehensive selection of machinery designed to meet various production needs. It is essential to analyze the features and capabilities of each machine, ensuring the right fit for the specific requirements of your woodworking projects.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4