Introduction

Drilling through wood requires not just any drill bit, but the right one. The world of wood core drill bits is vast, with each type designed for a specific task and material. From the common Twist Drill Bit to the precise Brad Point Bit, the efficient Auger Bits, and the versatile Forstner Bits, each has its unique features and applications. This article provides a comprehensive review of the different types of wood core drill bits, their uses, and factors to consider when choosing the right bit for your project. We will also delve into the importance of proper usage, cleaning, and storage for the longevity and performance of your drill bits.

Understanding Wood Core Drill Bits

A wood core drill bit, similar to a core drill bit used for masonry, is designed to cut large holes through wooden surfaces. The primary element of a core drill bit is the core drill bit or annular cutter, which is a hollow cylinder tipped with teeth or an abrasive surface. When engaged into the desired surface, the rotating core drill bit progressively cuts a ring-shaped hole, leaving a cylindrical piece of uncut material called a core. The size and diameter of a core drill bit determine how far it can go until it is full of core materials.

Types of Wood Core Drill Bits

Wood core drill bits come in various types, each designed for specific tasks. The Twist Drill Bit is common and used for general purposes. The Brad Point Bit is perfect for precise hole positioning. Spade Bits are ideal for boring larger diameter holes. Auger Bits use a threaded tip to pull the bit through the wood, making them efficient for deep drilling. Self-feeding Bits are suitable for boring larger holes. Installer Bits are used for installation work, while Countersink Bits drill a pilot hole and countersink the hole simultaneously. Forstner Bits are used for boring through wood or creating flat-bottomed holes. Lastly, Hole Saw Bits use a pilot twist bit to guide a large diameter rotary saw.

Spiral Bits

The Solid Carbide Downcut Spiral Bits with Chipbreaker are excellent for CNC wood working. These bits are made from solid carbide, ensuring durability and precision. They feature 3 negative helical cutting edges with a chipbreaker, providing an excellent edge finish on the top side. These bits are suitable for use on hardwoods, other wood types, laminates, and plastic materials. The chipbreaker feature helps in efficient chip removal, reducing the risk of bit damage and ensuring a cleaner cut.

Forstner Bits

Forstner Bits are a type of wood core drill bit available in various sizes, from 1/4 inch to 2-3/4 inches. They are ideal for drilling flat bottom holes and can be used with hand-held drills or drill presses. Forstner Bits are made from different materials like High-Speed Steel, Steel, High Carbon Steel, and Carbide. They come as individual pieces or in sets, and some sets include a carrying case. Prices range from under $10 to over $300.

Hole Saw Bits

Hole saw bits are a popular type of wood core drill bit, especially for larger holes. They are available in different diameters, from 1-1/2" to 2-1/2". The material of the bit can range from steel, carbon, high-speed steel, bi-metal, carbide, to high carbon steel. The price varies depending on the specifications, ranging from under $10 to over $300. They can be purchased individually or in sets, and are suitable for cutting through a variety of materials, including wood and wood with nails.

Factors to Consider When Choosing a Wood Core Drill Bit

Like most drill bits, wood bits have three main components. TIP: Go short. Any time you can use a short bit instead of a long bit, do it. Short bits are more accurate, more rigid which means less breaking, better in tight areas, and save money while increasing productivity because your crew isn’t distracted by changing bits frequently, less money spent buying replacement bits, and your project is that much closer to being on schedule.

Material Type

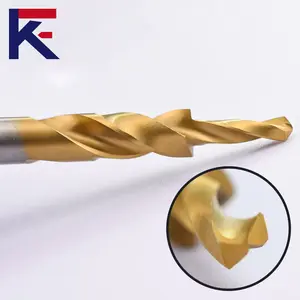

When choosing a wood core drill bit, material type plays a crucial role. Low carbon steel bits are affordable and suitable for softwood, but require frequent sharpening. High carbon steel bits, on the other hand, retain their shape longer and can cut harder materials. High-Speed Steel (HSS) bits are popular due to their wear resistance and ability to withstand high temperatures. Titanium coated bits offer high corrosion resistance and longer service life, making them ideal for repetitive drilling. Carbide-Tipped bits are hard and heat resistant, but brittle. Lastly, diamond bits are the hardest, suitable for the toughest materials, but come at a higher cost.

Bit Size and Shape

Understanding the size and shape of your wood core drill bit is crucial for optimal performance. Drill bit sizes are defined in terms of standard metric lengths, with British Standard BS 328 defining sizes from 0.2 mm to 25.0 mm. The size increments between drill bits become larger as bit sizes get smaller. For example, in the U.S., fractional inch and gauge drill bit sizes are common. In most other countries, metric drill bit sizes are the norm. The price and availability of particular size bits do not change uniformly across the size range. Bits at size increments of 1 mm are most commonly available and lowest in price.

Drill Bit Coating

Drill bit coatings significantly extend the lifespan of your wood core drill bits. The three most common coatings are Titanium Nitride (TiN), Titanium Carbon Nitride (TiCN), and Titanium Aluminium Nitride (TiAlN). TiN can extend tool life 2-4X that of uncoated drills. TiCN offers high hardness and can extend tool life 4-5X that of uncoated drills. TiAlN offers high heat and oxidation resistance that can extend tool life 4-10X that of uncoated drills. Choose the right coating based on your application and material.

Price and Brand

When considering the price of wood core drill bits, options vary. For instance, a top choice for wood drill bits can be priced at $29.97 for a 14-piece kit. Alternatively, other high-quality drill bits offer a 14-piece kit for just $19.32. On the higher end, a set designed for hardened steel is priced higher. Remember, the price often reflects the quality and durability of the drill bits.

Safety and Maintenance of Wood Core Drill Bits

Proper maintenance and storage of your wood core drill bits are crucial for their longevity and performance. Regular visual reviews of the general condition of the bits can help identify any potential issues early. Ensure the safety labels are readable to maintain proper usage guidelines. Check the electrical equipment and hydraulic hoses associated with the drill for any signs of wear or damage. Special attention should be given to maintaining the drill bits themselves, including the weight-on-bit controls and flushing equipment. Finally, ensure your bits are stored in a dry, clean place to prevent rust and damage.

Proper Usage

Proper usage of a wood core drill bit involves several best practices. Keeping the bits sharp is crucial for optimal performance. Mind your speed and torque when drilling, starting slowly and gradually increasing speed. It's also important to stop intermittently between drills to prevent overheating. Creating an initial indent before drilling ensures precision and accuracy. To avoid tear-outs, use techniques like taping and using a sacrificial board. Lastly, always observe safety measures, such as keeping hands straight and securing the workpiece properly.

Cleaning and Storage

Maintaining your wood core drill bits is crucial for their longevity. Regular visual reviews of their general condition can help identify any wear and tear. Ensure the safety labels are readable to follow proper usage guidelines. Check the electrical equipment and hydraulic hoses for any damage. Weight-On-Bit controls (WOB) and flushing equipment should be properly maintained. After use, clean the bits and store them in a dry place to prevent rusting. Remember, proper maintenance and storage can significantly extend the life of your wood core drill bits.

Conclusion

Choosing the right wood core drill bit is a crucial step in ensuring the success of your woodworking project. The type of bit, its material, size, shape, and coating all play a significant role in its performance and durability. Price is also an important consideration, reflecting the quality and longevity of the bits. However, even the best drill bit can fail if not used and maintained properly. Regular inspection, proper usage, cleaning, and storage are key to extending the life of your drill bits. With the right bit and proper care, you can achieve precise, clean cuts and efficient drilling, making your woodworking project a success.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4