What are Worm Gears

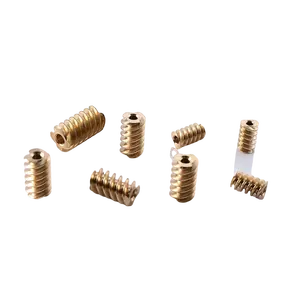

Worm gears are specialized gears consisting of a worm (which is similar in appearance to a screw) and a worm wheel, also known as the worm gear. This combination forms a compact, high-torque, and right-angle gear system. Worm gears are used across various industries and applications where a large gear reduction ratio or a non-backdrivable mechanism is required. The principle of operation for worm gears is based on the worm screw engaging with the teeth on the worm wheel, causing it to rotate.

Individuals and businesses involved in machinery design or repair, such as manufacturing plants, machinery repair shops, and construction works, find worm gears particularly useful. They can be integral parts of systems within farm equipment, food processing machinery, elevators, conveyors, and more. The unique attribute of worm gears is their ability to provide high reduction ratios and to handle heavy loads with relative ease.

The functioning of worm gears relies on the sliding contact between the teeth of the gear and the screw. When the worm (screw) turns, it pushes against the teeth of the wheel, causing it to rotate. Due to this sliding action, worm gears are generally less efficient than other types of gearing because of friction losses; however, this same attribute provides a self-locking feature under certain conditions.

Types of Worm Gears

Worm gears come in a variety of types and configurations to suit different applications and use cases:

Single-Start Worm Gear: This is a common type of worm gear where each complete turn of the worm advances the gear by one tooth. It offers high precision and is often used in applications requiring accurate positioning.

Multi-Start Worm Gear: These have multiple threads or "starts," which allow the gear to move more than one tooth per turn of the worm. Multi-start worm gears enable higher speed ratios and are useful in applications where quick movements are essential.

Duplex Worm Gear: This design allows for slight adjustments in backlash without changing the center distance. Duplex worm gears are beneficial in precision machinery where maintaining tight tolerances is necessary.

Hollow-Shaft Worm Gear: In these configurations, the central part of the wheel is hollowed out, allowing for versatility in mounting on shafts. This type can be found in conveyor systems and packaging machinery.

Each type has its specific advantages and common use cases that cater to various industrial needs, from heavy-duty machinery to precision instruments.

How to choose Worm Gears

When selecting worm gears for your business operations or product offerings on Alibaba.com, it is essential to consider several factors that align with your specific requirements:

Gear Ratio: Determine the desired speed reduction or torque increase needed for your application. A higher gear ratio means greater speed reduction but can result in lower efficiency due to increased friction.

Material: Choose a material that offers the durability required for your application while keeping cost considerations in mind. Materials range from metals like steel and brass to plastics, each offering different properties in terms of strength, wear resistance, and suitability for certain environments.

Load Capacity: Consider the amount of load that the gear will need to handle. A robust material like hardened steel may be necessary for heavy loads, whereas lighter loads could be accommodated by aluminum or plastic gears.

Customization Needs: If you have specific design requirements or need nonstandard dimensions for your application, look for suppliers who offer customization services like ODM (Original Design Manufacturing).

Supplier Reputation: Since reliability is crucial in mechanical components like worm gears, choose suppliers with good reputations who provide machinery test reports and support after-sales inquiries.

Best Worm Gears on Alibaba.com

When sourcing worm gears for industrial needs or resale purposes, Alibaba.com stands as a premier online marketplace that streamlines global trade across diverse sectors. With an expansive selection offered by numerous suppliers worldwide, Alibaba.com simplifies finding the right worm gear that fits specific operational requirements. From manufacturing plants to robotics applications, this platform connects businesses with high-grade components tailored for an array of mechanical setups.

The ease of use offered by Alibaba.com extends beyond product discovery; it includes features like mobile compatibility and multilingual communication tools that facilitate seamless transactions. Moreover, services such as Trade Assurance bolster buyer confidence by ensuring payment security until order fulfillment is verified.

Alibaba.com's commitment to aiding small and medium-sized enterprises is evident through its comprehensive approach that encompasses reliable supplier verification processes and transaction protection measures. This dedication ensures that businesses can source quality components such as worm gears with peace of mind, tapping into global supply chains efficiently regardless of their location or industry focus.

Common FAQs for Worm Gears

What is a worm gear?

A worm gear is a gear consisting of a shaft with a spiral thread that engages with and drives a toothed wheel. Worm gears are used to transmit power at 90 degrees and to increase torque while reducing speed.

How do worm gears work?

Worm gears work by the rotation of the worm, which resembles a screw, interacting with the worm wheel. This causes the wheel to move with a motion that is perpendicular to the axis of the worm, enabling significant torque multiplication and speed reduction.

What are the advantages of using worm gears?

The advantages of using worm gears include their ability to provide high torque at low speeds, their compact size for the amount of power they transmit, and their self-locking capability, which can prevent back driving in certain applications.

What materials are worm gears made from?

Worm gears are made from a variety of materials including steel, brass, stainless steel, aluminum, bronze, and various plastics. The choice of material depends on the application's requirements for strength, durability, and environmental resistance.

Are custom worm gears available?

Yes, custom worm gears can be produced to meet specific requirements for size, material, and performance characteristics. Suppliers may offer customization services like ODM to create gears tailored to unique application needs.

What industries use worm gears?

Worm gears are used in numerous industries including manufacturing plants, machinery repair shops, construction works, farm equipment, printing shops, food processing machinery, and many others requiring precise motion control and torque management.

How do I select the right worm gear for my application?

To select the right worm gear for your application, consider factors such as required gear ratio, load capacity, material properties, environmental conditions, and whether you need standard or custom dimensions. Additionally, assess the reputation and capabilities of potential suppliers.

Can worm gears handle heavy loads?

Worm gears can handle heavy loads depending on their design and material construction. It is vital to select a gear that matches or exceeds the load requirements of your specific application.

What is a single-start worm gear?

A single-start worm gear has a single thread or "start" on the worm. Each full turn of the worm advances the gear by one tooth. They are known for precision and are commonly used where exact positioning is crucial.

What is a multi-start worm gear?

A multi-start worm gear has multiple threads on the worm. This design enables faster movement of the gear per turn of the worm and is useful in applications requiring quick action or higher speed ratios.

How can I ensure I'm choosing a reliable supplier for worm gears?

To ensure reliability when choosing a supplier for worm gears on Alibaba.com, consider suppliers who provide detailed product specifications, machinery test reports, customization options if needed, and have positive customer feedback.

Are there different types of worm wheels to pair with my worm gear?

Yes, there are different types of worm wheels available that vary in terms of tooth design and material. The choice depends on your specific application needs such as load capacity and desired lifespan under operational conditions.

How does customization affect delivery times for worm gears?

Customization can affect delivery times as it requires additional design work and manufacturing processes tailored to your specifications. Communicate with suppliers regarding lead times when ordering custom-designed worm gears.

Can I find explosion-proof or waterproof worm gears for harsh environments?

Suppliers may offer special features like explosion-proof or waterproof construction for use in harsh environments. Ensure that the protective features meet the requirements of your application's operating conditions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4