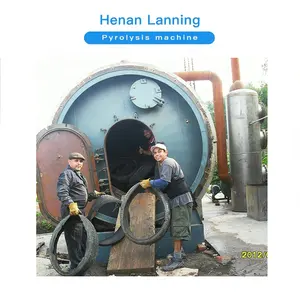

Introduction to 20 Ton Pyrolysis Plants

Pyrolysis plants are pivotal in the recycling industry, particularly for converting waste materials into usable products such as fuel. A 20 ton pyrolysis plant is a sizable industrial unit designed for processing large quantities of materials like rubber and plastic. This category of pyrolysis plant is engineered to handle up to 20 tons of input material, making it a significant investment for businesses in the recycling sector.

Core Components and Functionality

The core components of a 20 ton pyrolysis plant include a reactor, condenser system, and a fuel oil tank. These plants operate by thermally decomposing materials without oxygen, which means that the construction materials must be able to withstand high temperatures and corrosive substances. The reactor is the heart of the plant, where the pyrolysis process occurs, and it is typically made from robust materials that offer longevity and resilience.

Applications and Versatility

Pyrolysis plants are versatile in their applications. A 20 ton pyrolysis plant can process a variety of feedstock, including waste tires, plastic waste, and oil sludge. The end products, such as pyrolysis oil, carbon black, and combustible gas, have various applications in industries ranging from energy to construction. The adaptability of these plants to different input materials makes them valuable for businesses looking to diversify their waste processing capabilities.

Operational Features

Operational features of a 20 ton pyrolysis plant often include automation systems to ensure efficiency and safety. The use of a programmable logic controller (PLC) is common, allowing for precise control over the pyrolysis process. Additionally, the incorporation of safety features, such as pressure and temperature monitoring systems, ensures the plant operates within safe parameters.

Environmental Impact and Efficiency

The design of a 20 ton pyrolysis plant focuses on minimizing environmental impact. By converting waste into reusable materials, these plants play a crucial role in waste management and resource recovery. Efficiency is also a hallmark of modern pyrolysis plants, with advancements in technology allowing for higher output rates and improved energy consumption profiles.

Choosing the Right Pyrolysis Plant

Selecting the appropriate 20 ton pyrolysis plant involves considering factors such as the type of feedstock, desired output, and operational features. It is essential for businesses to evaluate the specifications of different plants to find one that aligns with their operational goals and capacity requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4